Marine Three-Way Ball Valve

Marine Three-Way Ball Valves have three channels, inlet, outlet and bypass. By rotating the ball, the connection between inlet and outlet can be disconnected or connected, and the connection between inlet and bypass can be disconnected or connected, so as to realize the purpose of regulating the flow or switching the flow direction. The three-way ball valve is easy to operate, only need to turn the handle or electric device to realize the switch or adjust the flow. Three-way ball valves can be applied to a wide range of media, including liquids, gases, steam, oil and so on.

Overview

Operation:

Marine Three-Way Ball Valves are usually operated by rotating the valve stem to control the opening and closing of the valve. In the opening process, when the handwheel is turned counterclockwise, the stem will move in the opposite direction and the spool will then detach from the seat and begin to rotate without friction until it reaches the fully open position. In the closing process, when the handwheel turns clockwise, the valve stem descends and causes the ball to leave the valve seat, the valve stem and the ball rotate at the same time, and finally the ball is pressed tightly against the valve seat to realize sealing.

Material:

The body and bonnet of a three-way ball valve are usually made of cast iron, stainless steel and other materials. The valve body and bonnet are connected by bolts to ensure the sealing performance.

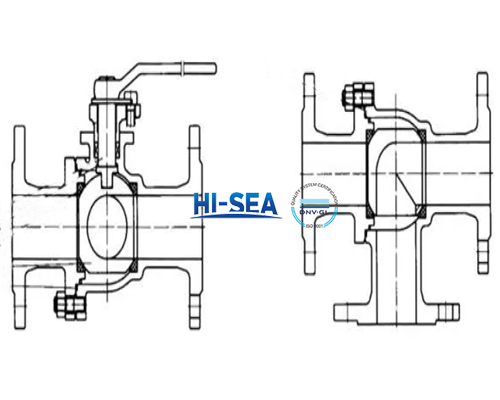

The ball of Marine Three-Way Ball Valves is one of its key components, usually made of stainless steel. The ball is inlaid with two T- or L-shaped runners for connecting three pipes. The contact surface between the ball and the valve seat is usually made of hard alloy material to improve sealing performance and wear resistance.

Drawing:

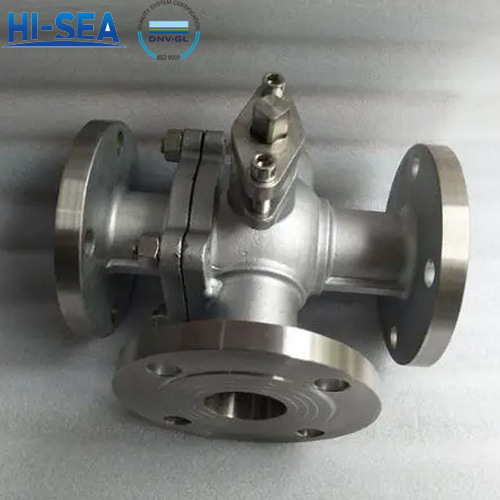

Picture: