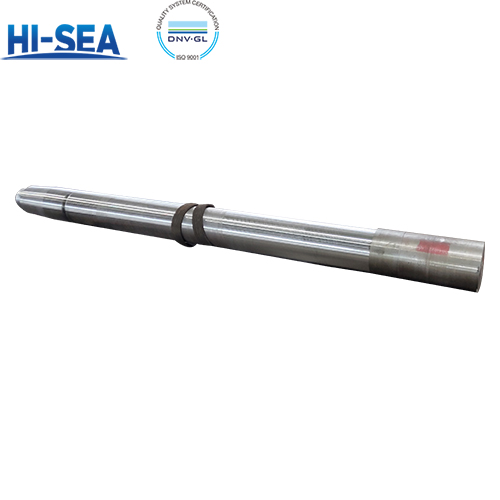

Marine Stern Shaft

Marine stern shaft generally refers to the shaft with a propeller in the last section of the ship shafting system. On some ships, due to the shape of the ship or the tilt of the shaft system, the shaft extends out of the hull. The last shaft equipped with the thruster is called the thruster shaft, and the preceding shaft extending outside the hull is collectively called the stern shaft.

The stern shaft and the propeller are fitted with a conical surface, and the stern shaft nut is used to press the propeller on the shaft. The thread direction of the stern nut must be opposite to the forward direction of the thruster to prevent loosening. When the stern shaft tube bearing is lubricated and cooled with outboard water, the parts of the stern shaft in contact with the outboard water (between the front and rear copper sleeves) are usually coated with glass steel for corrosion protection.

Overview

The stern shaft is a section of shaft at the end of the shaft system. The head end flange is connected with the middle shaft flange with a tight bolt. The end of stern shaft is conical in shape for mounting the propeller. The stern shaft is forged with high quality carbon steel, low alloy steel and stainless steel to ensure its quality and zero or minimal leakages over time. The sealing apparatus is necessary on the stern shaft to prevent oil leakage and seawater from entering the ship.

Features:

High versatility, great compatibility

Corrosion resistant

Durable and reliable materials

High strength and tenacity

Easy maintenance and inspection

Can be customized according to different needs

A marine stern shaft is essential for the propulsion of a vessel, designed to handle the unique challenges of operating in a marine environment. Proper maintenance and inspection are critical to ensuring its longevity and performance.