Marine Propeller

Marine propellers are generally made of nickel bronze and aluminum bronze, with structures consisting of three, four, or even five blades, and the blades have a certain inclination relative to the center. Facilitate the generation of tangential and normal forces relative to water during rotation. The geometric shape and data for manufacturing propellers include pitch, disc ratio, dynamic balance, static balance, diameter. Propellers on modern ships have both fixed pitch and variable pitch propellers.

Overview

A propeller is a propulsion system composed of several blades. It is a device that converts the power emitted by the main engine into driving the ship forward.

People have used various forms in long-term practice

The thrusters. The ancient ones had oars, and later invented oars and sails. With the emergence of engines, the Minglun thruster appeared, which consists of two huge rotating wheels installed on either side of the ship's hull or in the cabin (the origin of the ship's name). Later, propellers appeared and have been used ever since. It is usually installed at the stern of the ship. Propellers have the characteristics of simple structure, light weight, and high efficiency. The most commonly used propeller structures are three bladed propeller, four bladed propeller, and five bladed propeller. The connecting part between the propeller and the stern shaft is called the "shu". The propeller blades are fixed on the newspaper. When viewed from the stern to the bow, one side of the propeller blade seen is called the blade surface, and the other side is called the blade back. The connection between the blade and the hub is called the blade root, and its outer end is called the blade tip.

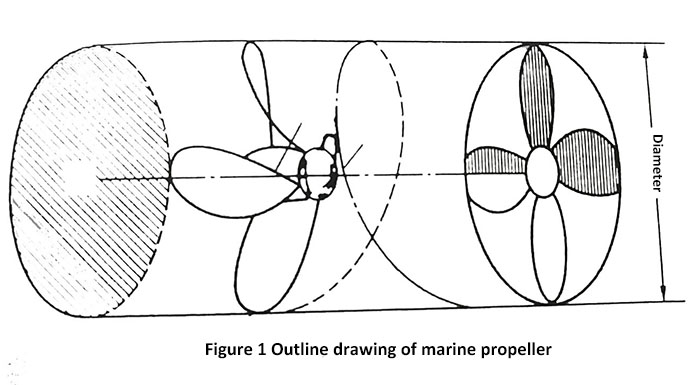

The circular trajectory of the rotating blade tip of a propeller is called the tip circle. The diameter of this circle is called the propeller diameter. This circle is called the propeller and its area is called the disk area, as shown in Figure 1.

The size of the propeller diameter depends on the ship's speed, main engine power, and rotational speed.

Based on the above three factors, the optimal diameter of the propeller can be determined. Generally speaking, the larger the diameter of the propeller, the higher the efficiency. However, the diameter of the propeller is subject to certain limitations, especially in shallow water channels.

The movement of the propeller is similar to that of the screw. Every time the screw rotates, it advances a certain distance forward in the nut. This distance is called pitch. The blade surface of a propeller is usually like the thread of a screw. The propeller moves in water, and water replaces the position of the nut. Moreover, water is flowing, so when the propeller rotates, it pushes the water backwards. According to the principle of force and reaction, water exerts a reaction force on the propeller, which is thrust, pushing the ship forward.

When the propeller is working, due to the reaction force of water on the blade surface, the blade must have a certain thickness to ensure its strength. The blade surface is a part of the helical surface, while the shape of the blade back is determined by the cross-sectional shape at each radius of the blade. The cross-sectional shapes of propeller blades usually include bow, wing, and crescent shapes.

The propeller is an important component with a complex shape and large size. The machining of propeller blades is relatively difficult, and various types of propellers have been machined using imitation or digital program controlled machine tools. The manual scraping and grinding of propellers is only applicable in individual situations.

Due to the high stress and harsh working conditions of propellers, their material requirements are relatively high. Marine propellers can be cast from metal materials such as brass, manganese iron brass, bronze, cast iron, and cast steel. Each material has its own characteristics. Copper has good toughness, high corrosion resistance, and good casting and processing properties, making it easy to polish and polish the surface. It is a commonly used material for manufacturing propellers, but it is relatively expensive. Cast iron is cheap in cost but has poor impact resistance. Although cast steel has high strength, its corrosion resistance is poor.

The pitch at each radius of the propeller blade is equal, which is called an equal pitch propeller, and the pitch that is not equal is called a variable pitch propeller. In addition, before installing marine propellers on board, they must undergo static balance tests and pitch measurements.

For more marine propeller information, kindly please click here.