Marine Propeller Shaft

The marine propeller shaft, also known as the stern shaft, is the critical link between the vessel's main engine and the propeller. It transmits torque while withstanding complex torsional vibrations, bending stresses, and the corrosive marine environment. At Hisea Marine, we engineer propulsion shafts that ensure optimal power transmission, alignment stability, and long-term reliability for vessels ranging from small workboats to large commercial carriers.

Overview

The marine propeller shaft is a critical component in a ship's propulsion system, responsible for transmitting power from the engine to the propeller. It converts rotational energy into thrust, enabling the vessel to move efficiently through water. This component must withstand extreme mechanical stresses, corrosion, and environmental conditions, making its design and maintenance vital for maritime operations. The marine propeller shaft enables propulsion. It operates underwater and must be designed to withstand harsh marine conditions. It can be oil and water lubricated to meet different demands of vessels.

The ship inspection code requires that the propeller shaft should be extracted to be repaired in the dock every three years. Users should check the scars and rust of the shaft neck, copper seal, ellipticity and taper limitation, and pay special attention to the crack damage of the propeller shaft cone.

Features:

Engineering Features | Technical Advantages |

High-Strength Alloy Steel / Stainless Steel Forging | Forged to standards such as CCS, BV, LR, etc., quenched and tempered, with yield strength ≥400 MPa, effectively resisting torsional fatigue and impact loads. |

Precision Machining & Dynamic Balancing | Journal surface roughness ≤ Ra0.4μm, taper and ovality control better than ISO 1940 G6.3 grade, reducing vibration and protecting the gearbox and propeller. |

Full-Size Non-Destructive Testing | 100% ultrasonic flaw detection + magnetic particle inspection, eliminating internal cracks and surface defects, compliant with classification society survey rules. |

Functions

Power Transmission: Transfers torque from the main engine to the propeller.

Thrust Generation: Converts rotational motion into forward/backward thrust.

Alignment Maintenance: Ensures smooth operation by minimizing vibration and misalignment.

Durability: Resists corrosion, fatigue, and torsional stresses in harsh marine environments.

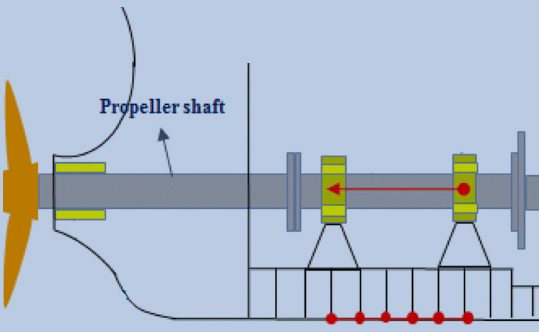

The Location of Marine Propeller Shaft