Marine Oily Water Separator

Marine Oily Water Separator is designed and manufactured in accordance with the provisions of the IMO MEPC.227(64) resolution "Guidelines and Technical Conditions for Anti-Pollution Equipment for Bilge Water in Machinery Spaces of Ships". This device is used for the bilge water treatment of various types of ships to meet the discharge standards stipulated in the IMO MEPC.227(64) resolution "Guidelines and Technical Conditions for Anti-Pollution Equipment for Bilge Water in Machinery Spaces of Ships" of the International Maritime Organization Convention before being discharged overboard.

This device features a compact structure, small size, light weight, strong processing capacity, reliable performance, and convenient operation and maintenance.

Our marine oily water separator operates by means of automatic/manual heating, automatic oil discharge, automatic alarm, and automatic recording of the operation process, etc. Manual oil discharge is also possible when necessary, and it is especially suitable for ships with a higher degree of automation.

As a professional supplier of ship equipment, we have rich experience in ship auxiliaries and are committed to providing you with the best quality solutions. Email <hs10@cqhisea.com>

Overview

Principle

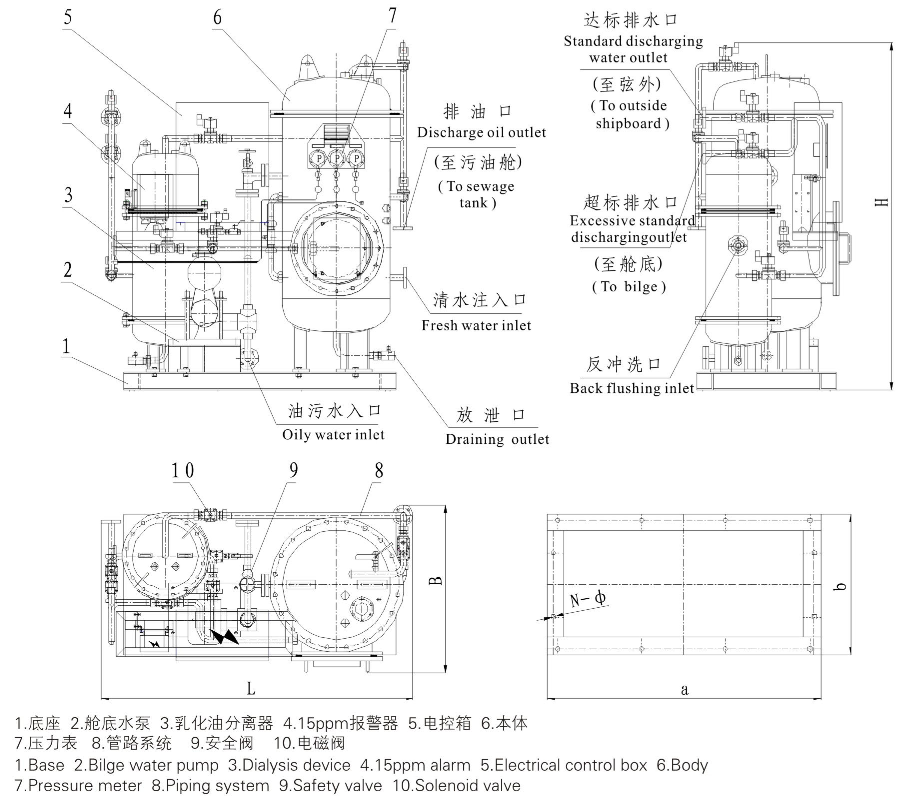

The marine oily water separator assembly consists of the separator body, special pump, electrical control box, 15ppm bilge water alarm device, suction filter assembly, and other pipelines, valves, and accessories, and it operates by using a three-stage oil filtering method.

The bilge water tank of the ship is equipped with a liquid level controller, which automatically controls the bilge water pump according to the water level. The bilge water is pumped into the first-stage oil filtering chamber of the separator, and the floating oil in the bilge water is separated from the water by utilizing the specific gravity difference between oil and water.

The coalescer in the second-stage oil filtering chamber coalesces and coarsens the fine oil particles in the bilge water to make them separate and float to the water surface for separation. The bilge water that meets the discharge standard after the second-stage treatment is directly discharged overboard.

If the bilge water after the second-stage treatment still fails to meet the discharge standard, the third-stage emulsified oil separation device will be automatically activated. The emulsified oil is separated into oil and water by physical methods to make the discharged bilge water meet the discharge standard and be discharged overboard. The separated dirty oil accumulates at the top of the oil filtering chamber. When the accumulated dirty oil reaches a certain amount, it can be automatically discharged to the dirty oil tank. The operation of the separator is fully monitored by the 15ppm alarm device to realize the switching of filtering levels and the automatic control of water discharge overboard or to the bilge.

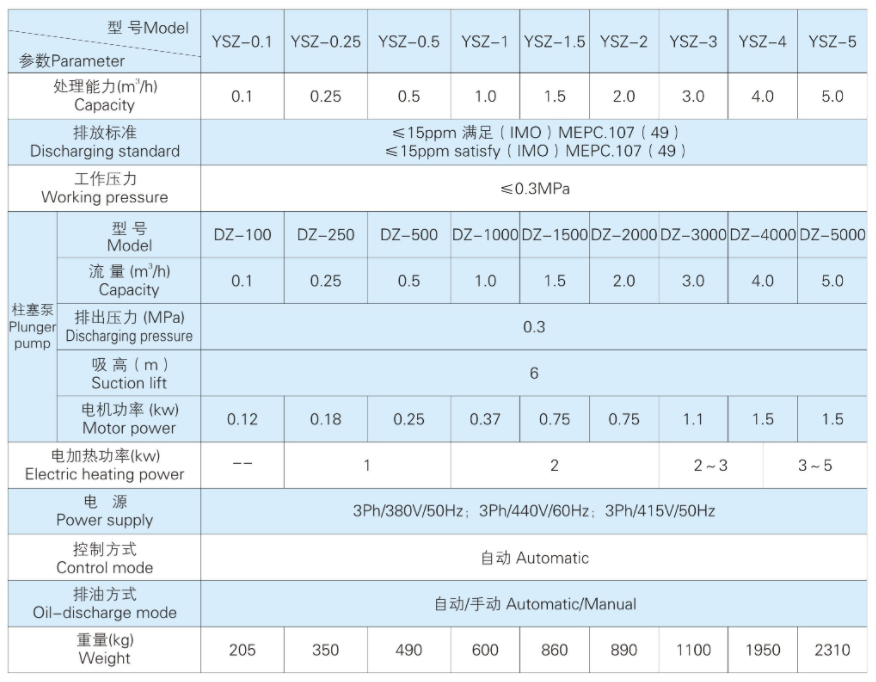

Main Technical Parameter

Structure Type

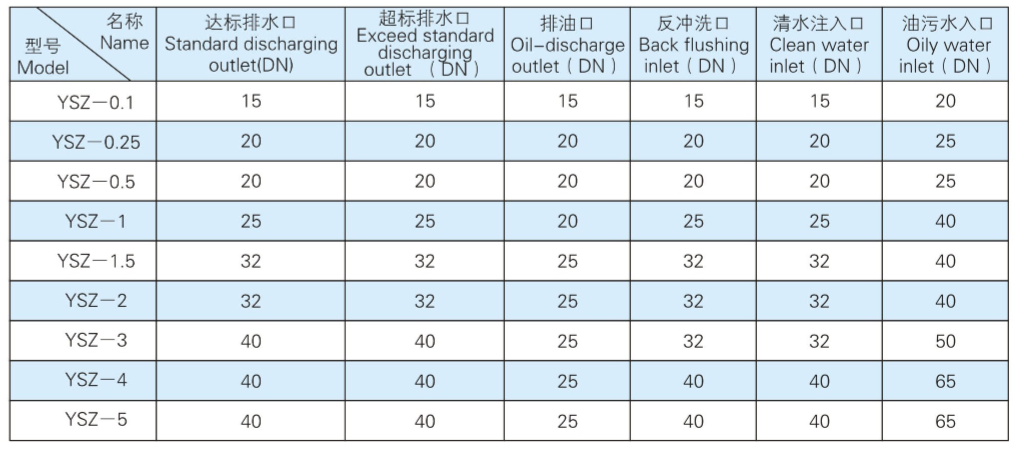

External Interface Size

Conclusion

By browsing this article, we believe that you must have a certain understanding of marien oily water separator. If you have procurement needs or want to learn more about the details or parameters in depth, welcome to visit the homepage of our marine oily water separator, or contact us directly!