Marine Hydraulic Double Gypsy Anchor Windlass

A hydraulic double gypsy anchor windlass is a piece of equipment used for anchoring a ship. It is usually driven by a hydraulic system and has a double anchor chain design to effectively control and operate the anchor chain on board. This equipment is very useful when the vessel is moored, anchored or when adjusting the length of anchor chains. The hydraulic system provides great power and control, enabling the vessel to complete the anchoring maneuver quickly and accurately.

Overview

A hydraulic double chain anchor windlass is a type of deck machinery used for anchoring and dropping anchors on ships. It is powered by a hydraulic system and is typically used on larger ships and boats to handle anchors and chains. It typically featured two gypsy wheels, and clutch will be necessary to control its running. The hydraulic double chain anchor windlass can be fitted with manual proportional valves for step-less speed.

It often uses cast steel or 316L stainless steel as its material to ensure its durability and reliability when facing harsh marine environment. Besides, proper installation and regular maintenance are essential for its better performance and safety. The hydraulic system requires periodic inspection, oil replenishment, and component lubrication to prevent malfunctions and ensure smooth operation.

Features

Driven by an hydraulic motor

Double gypsy wheel

Clutch and brake: manual or hydraulic

Can be equipped with drum and warping head as your requirements

Made of stainless steel

High quality, corrosion-resistant

Easy maintenance

Long lifespan

Local or remote control

Compact structure, small volume

Steady and safe operation

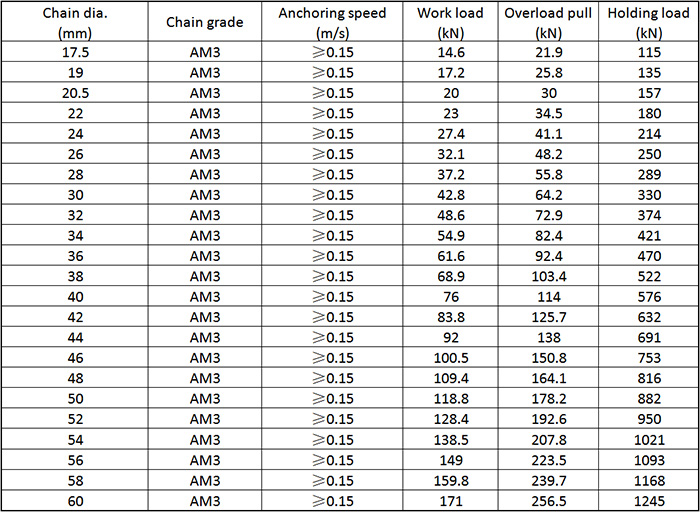

Main Technical Parameter (only for reference)