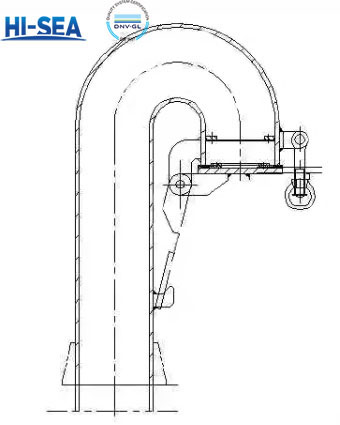

Marine Goose Neck Ventilator

Goose-neck ventilation tube can also make the air pressure in the cabin close to atmospheric pressure through inhalation and breathing, so as to prevent seawater, rain and sparks from entering the cabin, and at the same time, prevent sea waves from entering the ventilation tube and entering the cabin.

Overview

Main part:

Cylinder: the main part of the ventilation cylinder, which is used to guide the air flow.

Cylinder cover: it covers the upper end of the cylinder and is connected with the inner side wall of the cylinder through hinges, which is convenient for opening and closing.

Insect-proof net: installed inside the ventilation tube to prevent insects from entering the ventilation system.

Working Principle:

The operating principle of the marine gooseneck ventilator is also based on the principle of airflow dynamics, which utilizes temperature and pressure differences to achieve air flow. Typically installed on the roof or side of a ship, they allow fresh outside air to enter the ventilator through a wide opening and then pass through a narrow opening into the interior of the cabin. At the same time, the design of the ventilator also allows the dirty air inside the cabin to be discharged out of the cabin through the ventilator, thus forming a natural convection cycle and realizing the exchange of air inside and outside the cabin.

Marine gooseneck ventilators are usually made of seawater corrosion-resistant materials, such as stainless steel and aluminum alloy, to ensure their durability in the marine environment. Their design also takes into account the characteristics of the ship's structure and the requirements of the ship's appearance, which can harmonize with the ship's hull and ensure good ventilation.

Drawing:

Picture: