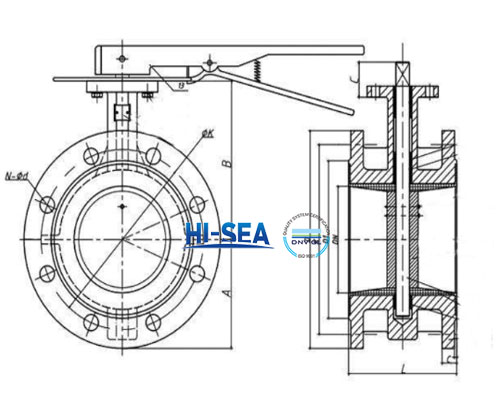

Marine Double Flanged Butterfly Valve

Butterfly valves have two types of connections: single flange and double flange. Single flange is to install a flange only on one side of the valve to connect the pipeline; double flange is to install a flange on both sides of the valve, which can be directly connected to the pipeline. Marine Double Flanged Butterfly Valve structure is more solid, because it can withstand greater impact and torque during installation, thus more stable and durable in use.

Overview

Installation:

1. Confirm the specification and model of the valve, check whether the appearance is intact, prepare the required tools and materials, such as flanged butterfly valves, flanges, bolts and washers.

2. Clean the flange surface on both sides of the pipe and the connection surface of the flange butterfly valve to ensure that the surface is clean, flat and free of impurities.

3.Put the two flanges of the flange butterfly valve over the pipe to be connected, align the bolt holes, and screw the two flanges together tightly with the bolts.

4. Use spot welding or welding to fix the flanges on the pipeline, wait for the welded joints to cool down, and then check the valves again to see if they are aligned.

5. Place the valve between the two pre-installed flanges, adjust the gasket position, gently insert the bolt nuts and tighten slightly to correct the flatness of the flange faces.

6. Calibrate the valve position, tighten all bolts and check that the valve opens and closes freely and that there is no leakage.

Drawing:

Picture: