Marine Double Eccentric Butterfly Valve

Overview

Design:

Double Eccentric Butterfly Valves can be designed in the form of rubber, PTFE and metal hard seals. For example, C-type, O-type or U-type metal sealing ring and other forms. If you want to make a taper to taper metal hard seal without interfering, sometimes the secondary eccentricity to do more, resulting in the need for a large eccentric torque, so that the open torque is too large.

Working Principle:

When the Double Eccentric Butterfly Valve is in the open state, the valve stem will drive the butterfly plate to rotate to 90 degrees so that the orifice of the butterfly plate is aligned with the pipeline, forming a smooth flow path that allows fluid to pass through.

When the Double Eccentric Butterfly Valve is in the closed state, the valve stem will continue to rotate, rotating the butterfly plate to 0 degrees, so that the orifice of the butterfly plate is perpendicular to the pipeline, thus completely cutting off the passage of fluid.

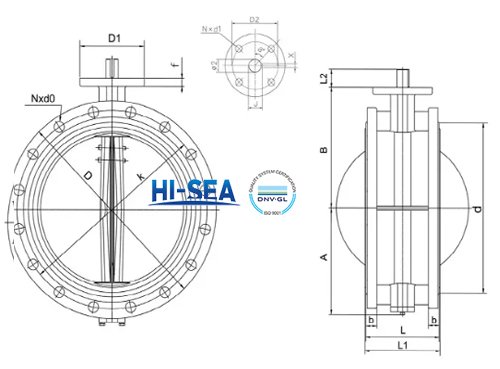

Drawing:

Picture: