Marine Blackwater and Graywater Treatment Plant

Marine sewage treatment equipment is a key equipment in Annex IV of the IMO International Convention for the Prevention of Marine Pollution by Ships (MARPOL 73/78), which is used to treat fecal sewage in the toilet sewer on board (also known as blackwater) to make it meet the international discharge standards and be discharged to the ship side. This equipment can also be used for the treatment of graywater on board, but the graywater should be pretreated (such as installing oil skimmers and hair filters) and a larger-capacity device should be selected to match. This series of devices comply with MEPC.159(55) resolution promulgated on October 13, 2006 and MEPC.227(64) resolution passed on October 5, 2012.

In addition to being applicable to the living areas of various large ships and oil platforms, this equipment can also be used for onshore domestic sewage, and the treated water quality can fully meet the national requirements for reused water quality.

In short, as a professional marine sewage treatment equipment supplier, with our excellent professional ability, high-quality product performance and a high sense of responsibility for marine environmental protection, we have become your reliable partner in the field of marine sewage treatment equipment. Choosing our products is to contribute to the protection of the marine environment, and it is to choose quality and peace of mind. Welcome to contact us by email <hs10@cqhisea.com>!

Overview

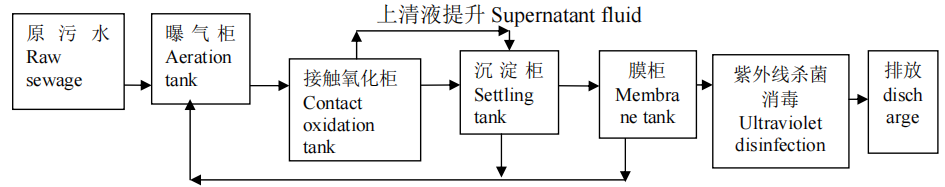

Principle Description

Our marine sewage treatment device utilizes the treatment principles of activated sludge, contact oxidation and membrane bioreactor (MBR) to degrade organic pollutants. The MBR can achieve efficient, thorough and clean treatment of blackwater and graywater, so that the discharged water can meet MEPC. 227. (64) and other possible more stringent requirements in the future.

Treatment Flow

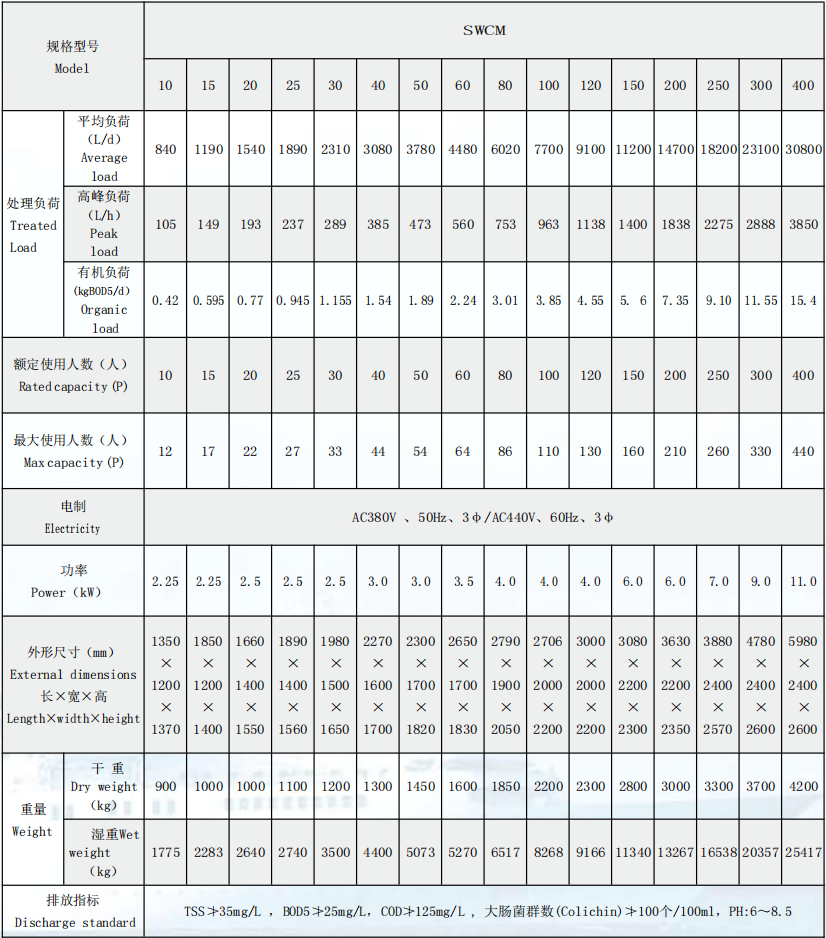

Specification

Adopting a horizontal cylindrical design with round heads at both ends, it is pressure-resistant and has a compact structure.

The device is fully automatic control and meets the requirement of 24-hour unmanned engine room.

Using the built-in "MBR" technology, the volume of the device is reduced, resolving the contradiction between the small cabin capacity and the large volume of the device.

This device suspends aeration in the biofilm cabinet and the hollow fiber membrane cabinet to form an "aerobic - anoxic" process to solve the problem of "nitrogen and phosphorus removal".

This device adopts patented technologies such as the automatic "air-lift method" of sludge in the sedimentation cabinet and the membrane cabinet, and the "online" cleaning of the membrane.

The application of the "online" cleaning technology makes the dirt on the membrane fall off automatically and restores the membrane flux, resolving the difficulty of opening for cleaning or replacing the membrane module due to the small cabin capacity.

After further treatment of the discharged water, it can meet the requirements of "reclaimed water reuse".

Technical Data

Note: We reserve the right to change the external dimensions of the device. The dimensions in the table are only for reference, and the specific dimensions shall be subject to the final confirmed drawing.

Conclusion

For additional details, please contact us! For other types of products, please feel free to contact us, or visit our Marine Sewage Treatment System homepage to learn more!