Marine Air Compressor

The Marine Air Compressor is a critical piece of equipment on any vessel, providing reliable compressed air for starting main engines, powering tools, and various control systems. Hisea Marine's robust and efficient compressors are engineered to withstand harsh maritime environments, ensuring uninterrupted operation and safety at sea.”

Overview

The marine air compressor is a type of machine designed to compress the air into rated pressure. Its application includes starting main and auxiliary engines. There are many types of marine air compressor structure, including different cylinder placement forms, tow stagea or three stages, single cylinder or multi-cylinder, air cooling or water cooling. The multistage type is more complex than the single-stage type, the weight is large, and the exhaust pressure is correspondingly large. The multi-cylinder type runs more smoothly than the single-cylinder type, and has less vibration, but also weighs more. The water-cooled type is better than the air-cooled type, but the air-cooled type is simple. Both the water cooled and air cooled air compressors are widely accepted on ships. The larger ships (especially naval vessels) that is a diesel-powered ship should also be equipped with an emergency air compressor driven by a diesel engine in addition to two main air compressors.

There are two lubrication methods of air compressors: splash lubrication and pressure lubrication. The splash lubrication is mostly used on small marine air compressors.

For more marine air compressor information, please click here.

Features

Feature | Benefit |

Compact Structure & Light Weight | Saves valuable space in the engine room and simplifies installation. |

Automatic Start/Stop & Stable Performance | Reduces manual intervention, ensures consistent air supply, and enhances fuel efficiency. |

Low Noise and Vibration | Creates a better working environment for crew members. |

Class Certifications (CCS, BV, RINA) | Guarantees compliance with international marine safety standards, facilitating vessel inspections. |

Key Applications of Our Marine Air Compressor:

Main & Auxiliary Engine Starting

Pneumatic Control Systems (for valves and automation)

Pneumatic Tools & Maintenance Work (blowing, cleaning)

Emergency Air Supply

FAQ:

Q: What is the difference between air-cooled and water-cooled marine air compressors?

A: Choosing the right cooling system is crucial for the efficiency and reliability of your marine air compressor. Here’s a detailed comparison to help you decide:

Feature Comparison | Air-Cooled Marine Air Compressor | Water-Cooled Marine Air Compressor |

Working Principle | Cools the compressor cylinder and discharge using ambient air and fans. | Utilizes the ship's central cooling water system (seawater/fresh water) for circulatory cooling. |

System Complexity | Simpler. No need for water connections, making installation easier and more independent. | More complex. Requires connection to cooling water pipelines, with higher installation demands. |

Cooling Efficiency | Dependent on ambient air temperature. Cooling efficiency may decrease in high-temperature environments or enclosed engine rooms. | More efficient and stable. Leverages the superior specific heat capacity of liquids, maintaining stable low-temperature operation even under high load and high-temperature conditions. |

Maintenance Requirements | Easier maintenance. Primarily involves cleaning fans and heat sinks, with no risk of water leakage. | Requires prevention of water circuit corrosion, scaling, and leaks, along with regular inspection of the water circulation system. |

Operating Noise | Typically higher, due to the presence of high-speed cooling fans. | Typically lower, with noise mainly coming from mechanical components. |

Space & Adaptability | More suitable for smaller vessels or auxiliary equipment with limited space and well-ventilated installation locations. | More suitable for large ships, main air compressors, or critical applications requiring continuous high-load operation. |

Typical Applications | Small fishing boats, auxiliary equipment control air, emergency air compressors, etc. | Merchant ships, cruise liners, naval vessels for main engine starting air systems. |

Q: What certifications do HI-SEA’s marine compressors have?

A: CCS, RINA, BV, etc.

Q: The difference between marine and industry air compressors?

A: Marine air compressors are asbestos-free, while land-based air compressors contain asbestos.

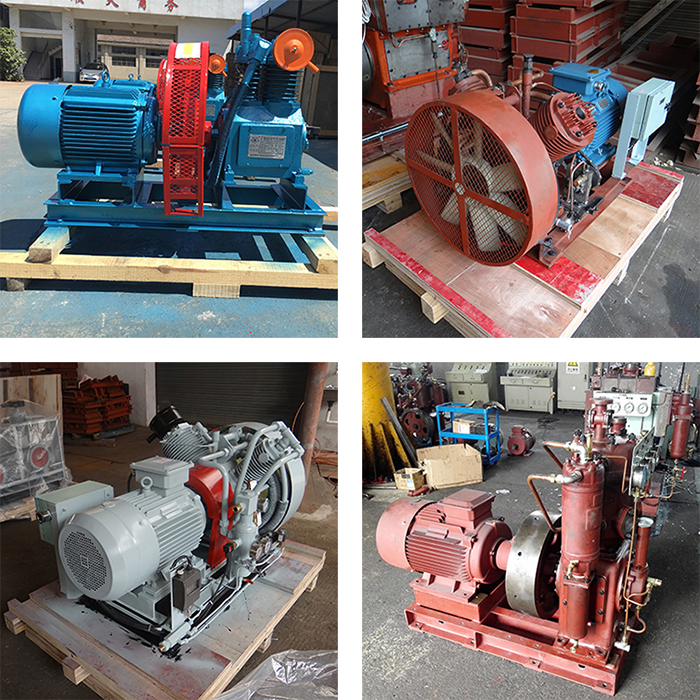

Images of Marine Air Compressor