Maintenance and Management of Marine Shafting System

The marine shaft system is an important component of a ship, responsible for transmitting power and enabling the ship to move forward. Therefore, regular maintenance is necessary to ensure reliable operation. The maintenance of the shaft system mainly includes:

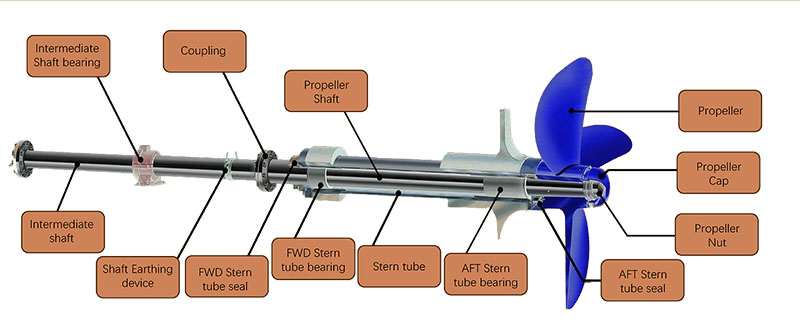

Regularly inspect the various components of the marine shaft system, including bearings, shaft sleeves, couplings, etc., to ensure that they are not worn or damaged.

Regularly check the lubrication of the shaft system to ensure sufficient lubricating oil and replace it in a timely manner.

Regularly clean all components of the shaft system to ensure that there are no accumulated debris or dirt.

Regularly monitor the temperature of the shaft system to ensure that the operating temperature of the shaft system is normal.

Overview

The shaft system, like diesel engines, should also be regularly maintained to ensure reliable operation. The maintenance of the shaft system mainly includes: daily maintenance, regular inspection and adjustment, etc

For more marine shaft system components, kindly please click here.

1. Maintenance of shaft system

(1)Before the ship sets sail, the fixing bolts of each shaft system and coupling flange should be checked for looseness. If there is looseness, it should be fixed in a timely manner to ensure safety during operation.

(2)For shaft systems lubricated with water, the grease part packing type sealing device should be appropriately opened with the packing gland before the ship sails to ensure that the shaft neck is lubricated without heating. When the ship is accompanying, the packing gland should be pressed purple to prevent seawater from leaking into the cabin. Lubricating with oil prevents oil leakage.

(3)For oil lubricated stern shaft systems, an appropriate amount of lubricating grease should be regularly and quantitatively added to the packing sealing device to ensure good lubrication of the transmission system.

(4) The stern tube device using gravity oil lubrication should regularly maintain the liquid level of the oil tank within a certain range to ensure the lubrication of the stern bearings.

The stern tube equipped with a hand pump for oil should be pressurized with a hand pump before the ship sails until oil flows out of the return pipe, and then the three-way valve should be turned to the position where it is connected to the gravity oil tank.

(5) For intermediate bearings that use oil cup lubrication, lubricating oil should be regularly added to each bearing during operation.

(6)During the operation of the shaft system, it is necessary to regularly check whether the shaft system is working properly. If there is vibration, abnormal operating sound, or bearing heating (temperature exceeding 65 ℃) in the shaft system, the cause should be identified and eliminated in a timely manner.

2. The content of regular inspections and adjustment requirements

During the operation of a ship, the moving parts such as the shaft neck and bearings of the shaft system will wear out, and the positions of the intermediate bearings, thrust bearings, gearbox, and main engine will experience varying degrees of relative displacement, which can cause changes in the centerline of the shaft system. Therefore, the shaft system should be regularly inspected to ensure that it operates in good condition.

The main contents of regular inspection and adjustment of the shaft system are as follows:

(1)Check the offset and deflection of each axis in the shaft system. If the offset and deflection values exceed the allowable range in operation, adjust them according to the method of aligning the shaft system to meet the requirements.

(2)Check the clearance between each intermediate bearing and thrust bearing. If the clearance exceeds the allowable range, adjust it to meet the specified requirements

(3)Check the quality of the lubricating oil for each bearing. If any metal powder is found to have deteriorated or viscosity is reduced, the lubricating oil should be replaced in a timely manner.

(4)Check the packing or oil seal ring of the stern tube sealing device. If excessive wear is found and the sealing performance is lost, it should be replaced in a timely manner.

Regular inspections of the shaft system can be carried out separately or in conjunction with maintenance of the main engine or ship repairs. Most regions follow the latter approach. During the operation of a ship, in addition to regular inspection of the axis, any changes in the centerline of the shaft system should be checked in a timely manner in the following situations. If any changes are found and exceed the allowable range, they should be adjusted in a timely manner:

(1). During operation, the lubrication of the shaft system is normal, but the temperature of the intermediate bearing or thrust bearing rises above the normal temperature (65C);

(2). The blades of the propeller are broken or severely deformed;

(3). After serious collision or grounding of the ship's hull.

In short, when managing and maintaining the shaft system, there should be equal emphasis on power devices such as the main paver. Due to a loss of understanding in material management operations and the occurrence of accidents. It will affect the normal navigation of the entire ship. Therefore, Li Mi has high requirements for the management, maintenance, and reliability of ship shaft system installation.

When managing the ship's shaft system, other factors that may affect the ship's shaft system should also be considered. For example, the impact of light and heavy load conditions on ships; The impact of ship speed status; The impact of wind and wave conditions on the ocean; And the impact of the overall layout deformation of the ship's own hull.