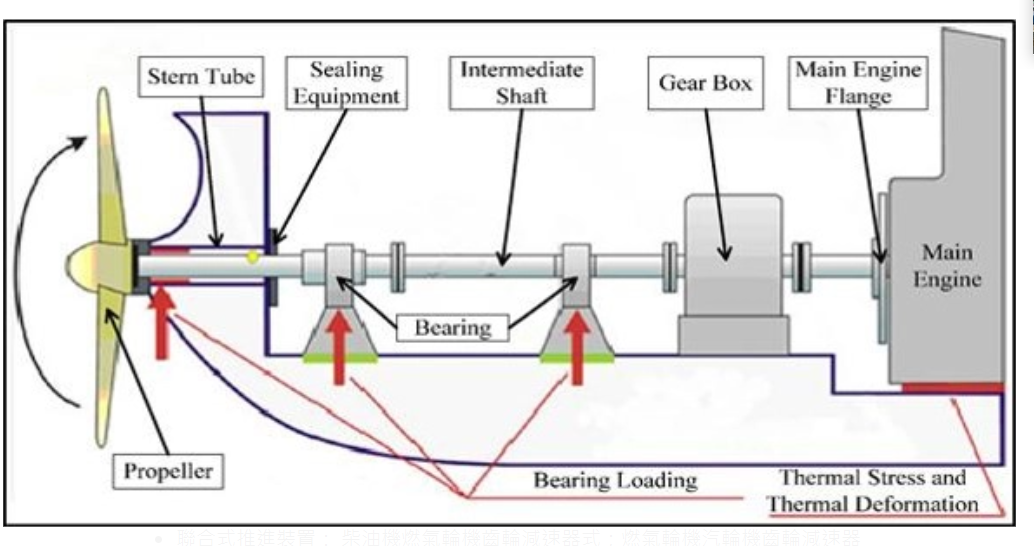

Installation process of marine shaft system

The installation of the shaft system is an important component in the construction of ships. The quality of the installation of the shaft system will directly affect the service life and reliability of the main engine and shaft system operation. Adopting the correct shaft installation process not only ensures the installation quality, but also greatly shortens the construction period. Due to the different forms of main engines and shaft structures used on various ships, their installation processes also vary. Due to differences in the production batch of ships, shipyard conditions, and process habits, even if the same ship is built, its installation process will also be different.

Overview

The installation process of the shaft system has a significant impact on the construction cycle of ships. Therefore, based on the actual situation, determining a reasonable installation process will have a great effect on the quality of shaft system installation and shortening the installation period.

For more marine shaft system components, kindly please click here.

During the process of ship construction, the deformation of the hull often has a significant impact on the installation quality of the shaft system. Therefore, the following conditions are required for the installation of the shaft system. Regardless of the process used, there are the following requirements for the hull:

1. The assembly and welding of the ship's hull are calculated from the stern, and more than 80% of the work has been completed,;

2. The watertight compartments within the axis range must undergo a watertight test and pass the acceptance inspection:

3. The bases (bases) in the host and shaft system devices should be welded and accepted as qualified;

4. Stop various operations with high impact and vibration;

5. Choose to carry out axis system cable lighting and alignment work at night or on cloudy and rainy days.

The main content of the installation process of the shaft system

1. Determine the centerline of the shaft system;

2. According to the theoretical centerline of the shaft system, carry out boring of the stern shaft tube seat hole or the herringbone frame hub hole, and the filling box hole of the compartment;

3. Install the stern tube, stern bearing, stern shaft, stern shaft sealing device, and install the propeller;

4. Install intermediate shaft, thrust shaft, etc., and do a good job in calibration;

5. Install the main engine (including reduction gearbox and clutch) and perform mutual calibration work;

After the above calibration work is completed, the couplings (flanges) in the shaft system can be connected and fixed.

Common installation methods for shaft systems

For a long time, the installation process of the shaft system has often been based on the stern shaft end after the ship is launched, in accordance with regulations

The offset value and tortuosity value are calibrated one by one from the stern to the bow and connected together. This process sequence reduces the impact of the E-shaped hull on the installation quality of the shaft system after the ship is launched, but the disadvantage is the long production cycle.

Shortening the shipbuilding cycle is one of the important measures to improve economic efficiency in order to meet the needs of exports. Therefore, safety work should be carried out as parallel as possible with ship construction projects, so in addition to the above installation processes, shipyards often use three installation processes: card and column.

1. Install both the stern shaft and the main engine simultaneously.

After boring holes according to the theoretical centerline of the shaft system on the shipway, install the stern tube, stern shaft, and propeller, etc. At the same time, the main engine is assembled according to the theoretical centerline of the angular axis system in the cabin. After being launched, the intermediate shaft can be installed, and this process sequence is limited to ships with more intermediate components.

2. Install the host first, and then install the shaft system.

First, install the main body according to the theoretical centerline of the shaft system, and then use the main engine as a reference to process and install the stern shaft and screw propeller. The characteristic of this process sequence is the installation of various parts and components of the main engine, which can be synchronized with the installation of the shaft system to the greatest extent possible. This is extremely beneficial for shortening the cycle and improving the quality of shaft system installation.

3. The installation work of the main engine and shaft system is completed on the shipway.

This T-craft method is only suitable for small ships produced in batches. But it is necessary to have prior knowledge of the deformation of the ship's hull before allowing direct calibration and installation of the annual shipyard (dock).

At present, the installation process sequence of shaft systems in shipyards is mainly based on the previous two methods.