How to Deal With Valve Packing Leakage

Valve packing leakage refers to the leakage of media from valve packing due to poor packing seal or other reasons during the operation of the valve. At the same time, the leakage problem of the valve, the proportion of the packaing is the largest.

Overview

►Reasons for Leakage:

1. Incorrect packing selection, not resistant to corrosion of the medium, not resistant to the use of the valve high pressure or vacuum, high temperature or low temperature;

2. Packing installation is not right, there is a small instead of large, spiral coiled joints are bad, on the tight down loose and other defects;

3. Packing more than the use of the period, has been aging, loss of elasticity;

4. The valve stem is not accurate, with defects such as bending, corrosion, wear and tear;

5. Insufficient number of packing circle, the gland is not pressed;

6. Damage to the gland, bolts, and other parts, so that the gland can not be pressed;

7. Improper operation, excessive force, etc;

8. Skewed gland, too small or too large a gap between the gland and the valve stem, resulting in stem wear, packing damage.

►Maintenance method:

1. The material and type of packing should be selected according to the working conditions;

2. According to the relevant provisions of the correct installation of packing, packing should be placed by circle pressure, joints should be 30 ℃ or 45 ℃;

3. The packing with long service life, aging and damage should be replaced in time;

4. Valve stem bending, wear and tear should be straightened, repair, serious damage should be replaced in a timely manner;

5. Packing should be installed according to the specified number of laps, the gland should be symmetrically and uniformly tightened, and the pressure sleeve should have a preload clearance of more than 5mm;

6. Damaged gland, bolt and other parts should be repaired or replaced in time;

7. Operation regulations should be observed, except for the impact handwheel, to operate at an even speed with normal force;

8. The gland bolts should be tightened evenly and symmetrically, and the gap between the gland and the valve stem is too small, the gap should be increased appropriately; the gap between the gland and the valve stem is too large, it should be replaced.

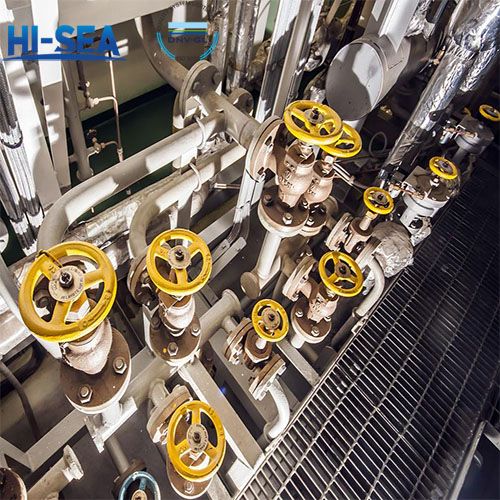

Valves are Installed on the Ship: