How to calibrate an oval gear flow meter?

Oval gear flowmeter measurement accuracy, suitable for high viscosity media flow measurement, but not for fluids containing solid particles (solid particles will be gear jammed, so that the flow can not be measured). If the measured liquid medium is mixed with gas, will also cause measurement errors. The greater the viscosity of the medium, from the gears and measuring space gap leakage out of the leakage is smaller, so the viscous skin of the core measurement medium is larger, the smaller the leakage error, the more favorable to the measurement.

Overview

Procedure:

1. Fix the oil outlet of the oval gear flow meter on the top of the standard gauge to ensure that the diesel oil can be smoothly discharged into the standard gauge, so as to reduce the error generated by the instability of the oil outlet.

2. Start the oil pump, so that the outlet pipe is full of oil and overflow to stop the oil pump, exhaust all the remaining diesel fuel in the standard gauge, start recording the oval gear flow meter scale value to be checked.

3. Start the oil pump to the standard gauge oil injection 50L, in close to 50L should be hand-controlled slow injection rate, to be stabilized at the oil level of 50L, write down the oval gear flowmeter scale value H. In order to observe and calculate the convenience of the oval gear flowmeter can be adjusted to the whole number of the method of the 2 checking the value of the scale, the key is to fix the standard gauge of the oil inlet.

4. The standard gauge of diesel fuel all discharged (with other oil drums contain), and then close the discharge valve.

5. Restart the oil pump, repeat 2, 4 steps, continuous 3 measurements, set 3 measurements when the standard gauge readings were h, h, h, then the basic error R (H - h) / H * 100%, if the average basic error R - in the allowable range of the basic error is qualified.

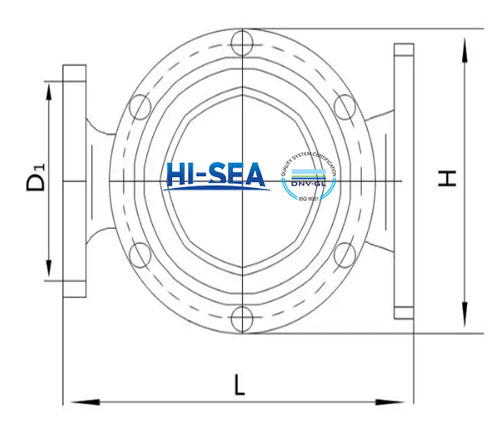

Drawing:

Picture: