Flush Type Sounding Pipe Head

Overview

Suggestions for sounding tubes

A covering plate shall be provided at the lowest part of the sounding tube to prevent damage to the hull. When using a bottom closed sounding tube, the sealing plate should be properly strengthened. For some vessels where ballast water sampling is done through the sounding pipe, note the location of the grooves in the sounding pipe and cut several holes along the length to ensure that the ballast water is better mixed in the sounding pipe. According to the practice of some ships, the use of overflow method to replace ballast water is that the whole length of the sounding pipe with fewer holes, the water in the pipe is not affected when the ballast water is replaced, in addition, the ballast tank is emptied and re-filled, due to the vacuum effect in the sounding pipe, the ballast water remains in the pipe. Therefore, it is recommended that shipyards should make as many holes as possible when making sounder pipes, so as to facilitate the mixing of ballast water in the pipes and water in the tank.

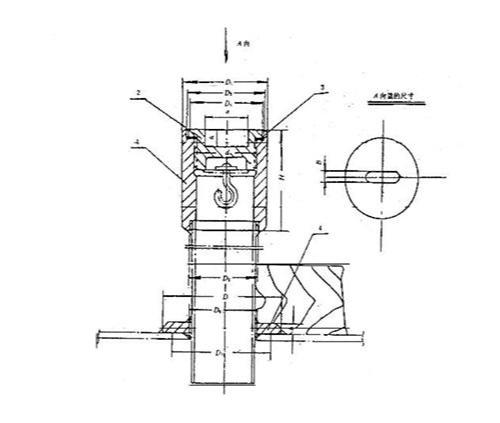

Drawing

Images of Flush Type Sounding Pipe Head