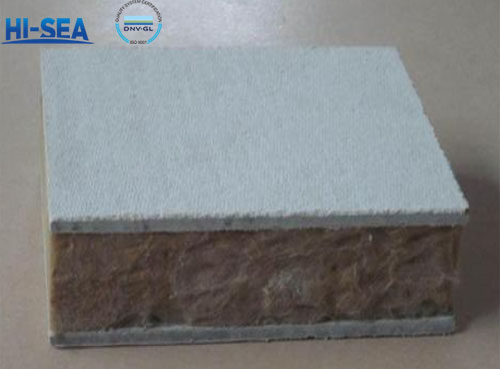

Floating Floor for Ship Use

Floating Floor for Ship Use is a new type of flooring made by using certain moisture-proof treatment technology, which can be applied to all kinds of ship floor decoration. Compared with traditional flooring, marine floating floor has excellent moisture-proof, shock-proof, fireproof, wear-resistant, easy maintenance and other characteristics, is currently the preferred material for floor decoration in the field of ships.

Overview

Installation steps:

First of all, you need to clean up and deal with the foundation, keep the surface level, no obvious cracks and mortar, the location of the drainage outlet needs to be reserved, and to ensure that the ground level to meet the demand. Then, the area where the floor will be laid is marked out with an ink line or level for subsequent construction.

According to the actual situation, lay suitable moisture-proof materials under the floor, such as PVC film. Then, place the marine floating floor on the foundation according to a certain direction and fix it on the foundation by floor glue. Note that a proper gap should be reserved between each piece of flooring to facilitate heat dissipation and contraction and expansion.

After the floor glue is dry, the floor can be spliced. Align the gaps between two adjacent pieces of flooring and insert the appropriate glue core to achieve a better splicing effect.

After the floor splicing, can be trimmed. If the gap is too wide or the floor warps and other phenomena, can be adjusted through the rubber hammer, screwdriver, so that the gap between the floor is uniform and the ground is flat.

Adjustment refers to the central area of the ground to produce layering, height, undulation and other situations, by adjusting the floor will be balanced, so that the ground is more level. Adjustment, need to pay attention to the floor cut location and material fall and other factors.

When the splicing joints of the floor are exposed, use the floor glue to apply glue at the joints so that the joints are no longer cracked.

After the caulking is dry, it can be sanded to make the surface of the floor more smooth and delicate. When sanding, you need to pay attention to the sanding direction and angle, as well as the speed of the sanding machine.

Picture: