Dredging Discharge Rubber Hose

The dredging discharge rubber hose is a pipe that carries mud out of the dredger. There are floating discharge rubber hose and non floating discharge rubber hose. The floating discharge rubber hose can be floating above the water, while the non floating discharge rubber hose is installed between steel pipes to make the pipeline more flexible. It is used for slit conveyance with dredgers. It is used not only as a connecting hose between a cutter dredger and a discharge line, but also as a jet water hose as a floating steel pipe line. Its diameter can be designed to be 200mm to 1300mm and working pressure 4bar to 45bar.

Overview

The dredging discharge rubber hose is designed to withstand the harsh conditions of dredging operations, including abrasive materials like sand, gravel, and silt. They are built with robust materials and multiple layers of reinforcement. It can be highly flexible to handle the dynamic movements and bends of dredging operations. This flexibility helps in managing the hose’s alignment and reduces stress on the hose and its connections.

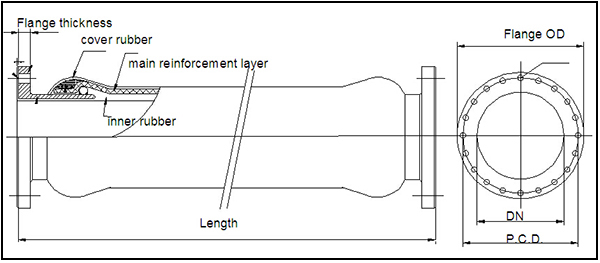

Structure and Material:

1. Cover: composed of natural rubber and synthetic rubber.

2. Reinforcement layer: composed of high strength rubber dipped chemical fiber and reinforced by spiral metal wire.

3. Inner rubber liner: composed of wear-proof natural rubber and synthetic rubber.

Feature:

Working temperature: -20℃ to +50℃.

Convenient to install, flexible and safe to use.

Excellent performance of abrasion-resistant and bending resistant.

Good quality, long service life

Anti-corrosion and shock

Accurate size, durable materials

Good mechanical properties

It can be customized according to different needs.

Drawing for Dredging Discharge Rubber Hose

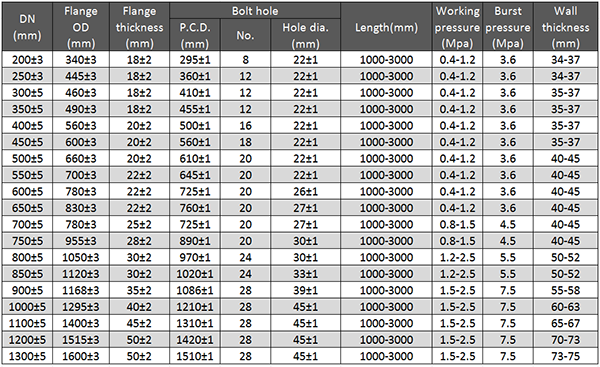

Main Technical Parameter