Dredging Cutter Teeth

Dredging cutter teeth and adapters can be used on various types of dredging equipment. We have more than 10 years OEM experiences for the first class brands of the world. The cutter teeth are available on cutter heads, dredging wheel and drag heads. Teeth and adapters are available in several types and different sizes. Their shape, material and fixation system, combined with their strength and reliability make a major contribution to improving production. The alloy steel material after the heat treatment has the characteristics of high hardness and toughness, outstanding wear resistance, especially suitable for the strong wearing working conditions.

Overview

Dredging cutter teeth are essential components of cutter suction dredgers (CSDs), used primarily in the dredging industry to break up and remove sediments and materials from the seabed or riverbed. These teeth are attached to the cutter head, which rotates and cuts through various types of materials such as sand, clay, gravel, or even harder substances like rock.

Material and Design:

Cutter teeth are typically made from high-strength steel or other durable materials that can withstand harsh underwater conditions and abrasive materials.

The design of the teeth varies depending on the type of material being dredged. Some teeth are designed with pointed ends for cutting through harder materials, while others may have a broader, flatter design for softer sediments.

Types of Cutter Teeth:

Pointed Teeth: Used for harder materials like rock or compacted soils.

Flat Teeth: Used for softer materials like clay or loose sand.

Chisel Teeth: Designed for breaking up rock and other tough materials.

Pick Teeth: Often used in dredging operations involving very hard rock or similar materials.

Features

Various types of teeth like wide chisel, narrow chisel and pick point

Various types of adapters like ACR adapter, adapter weld on nose and adapter leg

Wide chisels are used for peat, sand and soft clay

Narrow chisels are applied in packed sand and firm clay

Teeth with pick points are used for rock

Special mounting geometry

Replacement and Maintenance:

Cutter teeth are subject to wear and tear and must be regularly inspected and replaced to maintain the efficiency of the dredging operation.

They are typically bolted or welded onto the cutter head, allowing for relatively easy replacement.

Specification

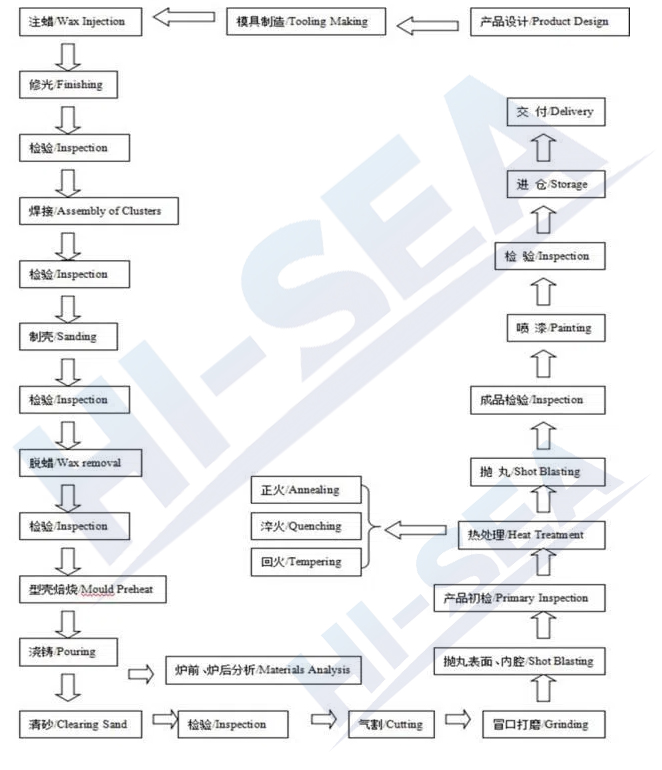

Production Process of Dredging Cutter Teeth

Dredging Cutter Teeth Image

Dredging Cutter Teeth Packing