DN40 Air Water Separator

Overview

Air water separator maintenance recommendations

As an important equipment, the air water separator needs regular maintenance to ensure its normal operation and extend its service life. The following are recommendations for maintenance measures:

1. Regular inspection: Regularly check the operating status of the air water separator, including checking whether the connecting pipe is loose, whether the drainage port is unblocked, etc., timely find the problem and repair it.

2. Cleaning and maintenance: Regularly clean the inside of the air water separator to remove accumulated dirt to ensure the normal operation and separation effect of the equipment.

3. Replace the filter element: according to the use situation, replace the filter element of the gas-water separator in time to ensure the separation effect and the life of the equipment.

4. Tighten the bolts: Periodically check whether the bolts in each part of the air water separator are fastened. If any problems occur, handle them in time.

5. Lubricating bearings: Regularly lubricate the bearings of the air water separator to ensure its normal operation.

6. Adjust the gap: If the gap of the air water separator changes, it needs to be adjusted in time to ensure its normal operation.

7. Drainage and discharge: After each use, it is necessary to dump the residual liquid in the air water separator in time, clean the equipment and dry it.

8. Every part of the equipment should be checked daily to ensure that all parts are not loose and damaged.

9. Regularly clean the inside of the air water separator, remove the internal sediment, maintain the appearance of the equipment, and ensure that the equipment is clean.

10. Sealing inspection: Regularly check the sealing condition of the equipment, check whether the sealing ring is aging, cracked or damaged.

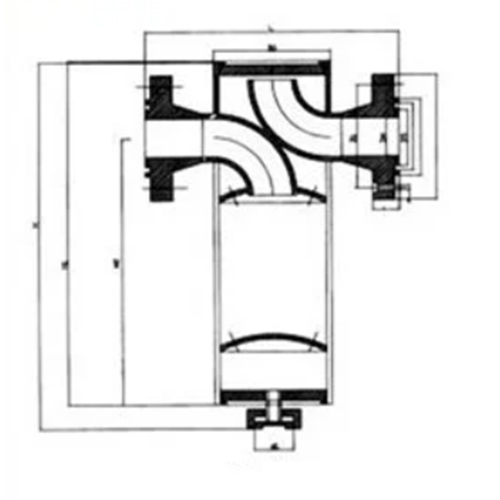

Drawing

Images of DN40 Air Water Separator