DN1200 Dredging Ball Joint

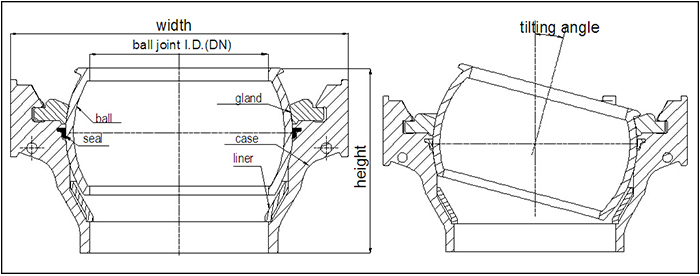

The DN1200 dredging ball joint allows for movement in multiple directions. Its tilting angle can be 15 or 18 degrees. This flexibility is crucial for accommodating shifts in the pipeline due to waves, tides, or the dredging vessel's movement. It permits the pipes to rotate relative to each other, which helps in reducing stress on the pipeline and prevents damage that could occur from rigid connections.

Feature:

Corrosion resistant

Wear resistant, no leakage

High durability, reliability and flexibility

Low maintenance cost, easy installation

Low maintenance cost

Overview

The ball joint is designed to maintain a secure seal, even while allowing for movement, to prevent leaks of the dredged material. It is usually made from strong materials like steel, and often treated to resist abrasion and corrosion. The DN1200 ball joint is built to withstand the harsh conditions of dredging operations, including the abrasive nature of the dredged material and exposure to seawater.

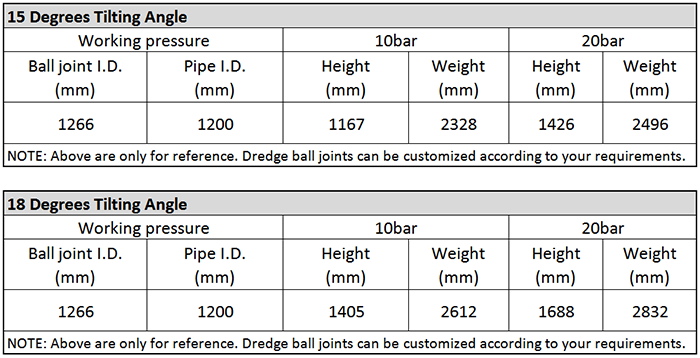

Dredge ball joints type:

1. Tilting angle of 15 degrees: 10bar, 20bar and 30bar.

2. Tilting angle of 18 degrees: 10bar, 20bar and 30bar.

Materials:

CASE: ZG30Mn GLAND: ZG30Mn BALL: ZG30Mn

LINER: ZG30Mn or 30CrMoNi SEAL: NBR LOCK: Q345 or Q235

Drawing for DN1200 Dredging Ball Joint

Main Technical Parameter