Detailed Explanation of Heat Transfer Plate of Plate Heat Exchanger

The main functional structure of a plate heat exchanger lies in its heat transfer plates, which are the core components for achieving efficient heat transfer. These heat transfer plates have extremely precise design and manufacturing techniques, and with their unique shapes and arrangements, they create ideal conditions for the rapid transfer of heat. The heat transfer plates can greatly increase the heat exchange area, enabling a large amount of heat exchange within a limited space. They are usually made of stainless steel or titanium alloy materials, and the special treatment of their patterns can ensure good heat transfer performance, allowing heat to be smoothly transferred between two fluids. This article will conduct an in-depth discussion on it. Thank you in advance for your browsing.

Overview

With the continuous progress of technology, the performance of the heat transfer plate is still continuously improved and optimized to adapt to the increasingly complex and diversified application scenarios, providing solid technical support for the development of various industries including the shipping industry. This article will explore the related contents such as the structure, performance and maintenance of the heat transfer plate.

The structure of heat transfer plate:

All plate heat exchangers look very similar from the outside. The difference lies within, in the details of the plate design and the sealing technology used.

An important aspect to consider when evaluating a heat exchanger is the form of the corrugation of the heat-conducting plate. These corrugation designs of the heat-conducting plates can prevent laminar flow and promote turbulent flow, greatly increasing the heat transfer rate, while also reducing the possibility of deposition on the plate surface and reducing maintenance. There are roughly two types of corrugations: herringbone corrugation and zigzag corrugation. Generally speaking, in a given increase in pressure drop, the zigzag corrugation will produce a greater heat transfer enhancement effect. But in actual design, manufacturers usually splice the herringbone corrugation and the zigzag corrugation design on the same heat-conducting plate.

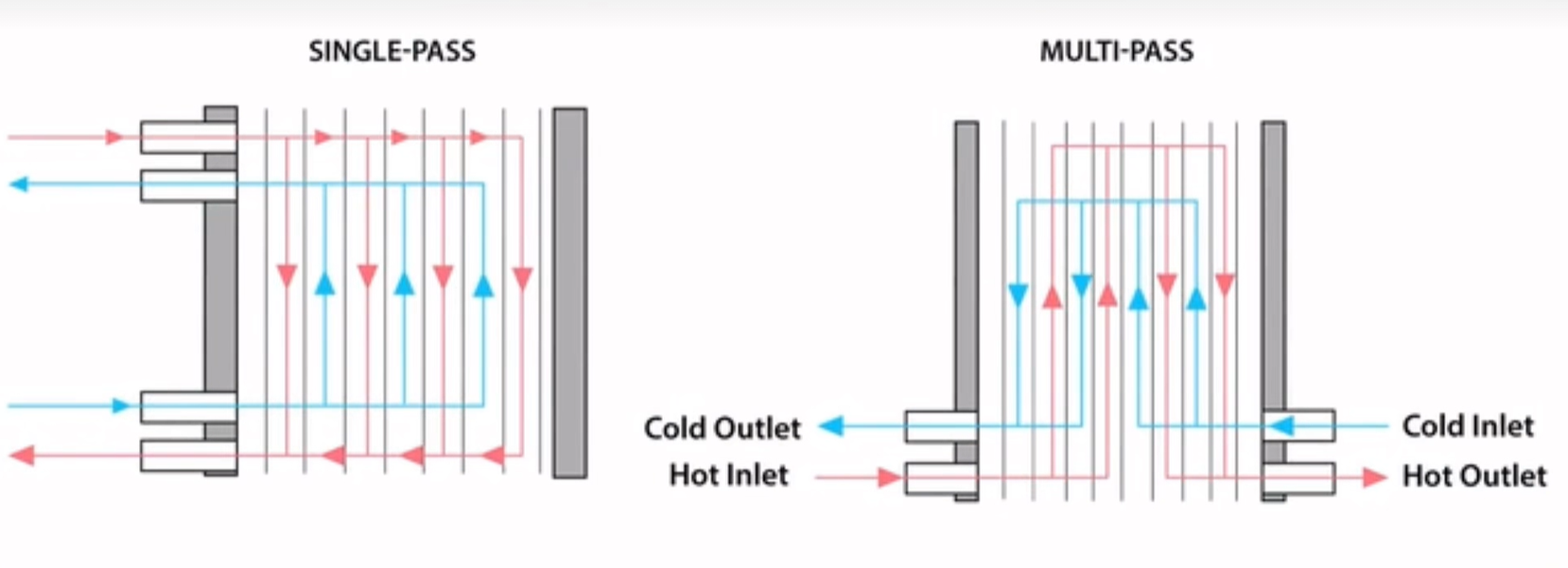

In addition to the design of the waveform, the single-pass or multi-pass fluid channels of the heat-conducting plate are also important factors affecting the efficiency of the heat exchanger. Compared to the single-pass design, the multi-pass design causes the two fluids passing through the heat exchanger to have multiple convections.

In addition to the design of the waveform, the single-pass or multi-pass fluid channels of the heat-conducting plate are also important factors affecting the efficiency of the heat exchanger. Compared to the single-pass design, the multi-pass design causes the two fluids passing through the heat exchanger to have multiple convections.

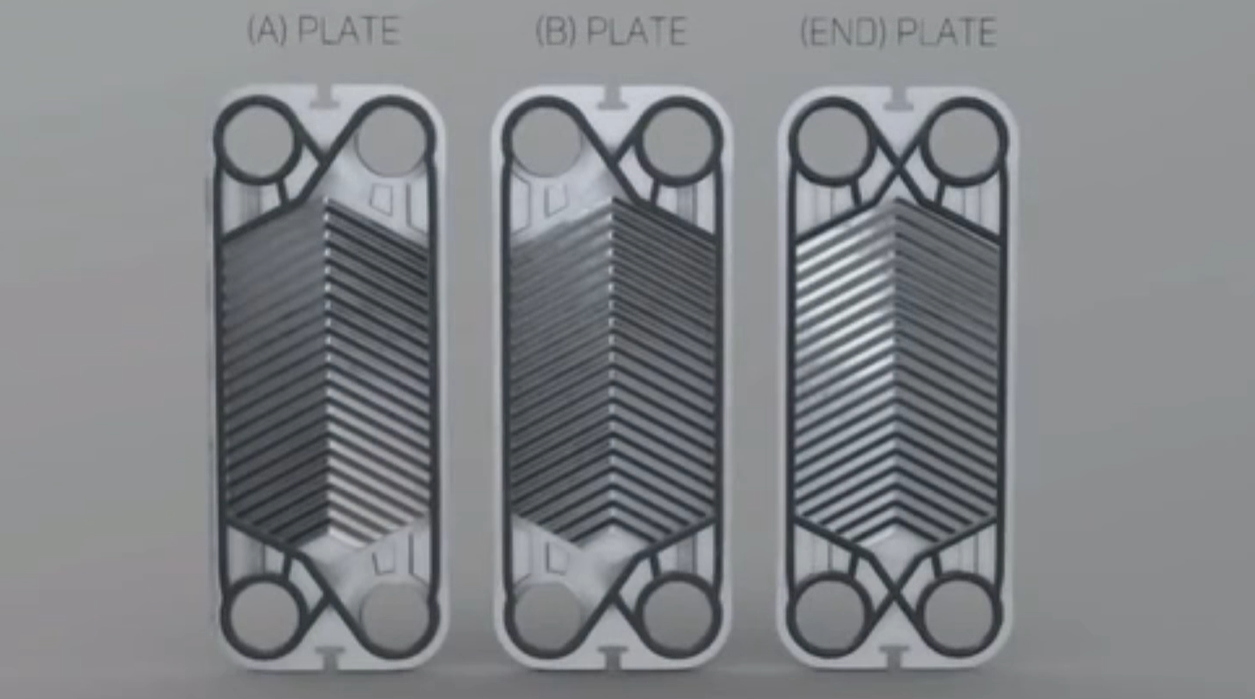

There are usually three types of heat transfer plates used alternately on a plate heat exchanger, which are respectively used as the hot fluid channel, the cold fluid channel, and the sealing plates at both ends of the heat exchanger.

Cleaning of the heat transfer plates:

Regular cleaning (on-site cleaning) is the most effective way to wash away all the waste and dirt that reduces the efficiency of the heat exchanger over time. This method requires emptying both sides of the plate heat exchanger and then isolating it from the fluid in the system. It should be rinsed with water from both sides until the water is completely clear. For the best results, the rinsing should be in the opposite direction to the regular operation direction. After that, it's time to use a circulation pump and a solution tank to transfer the cleaning agent, while ensuring that the agent is compatible with the gaskets and plates of the plate heat exchanger. Finally, the system should be rinsed with water again before the discharge flow is clear.

Conclusion:

That's all for this article. In this article, we introduce the basic structure, performance and cleaning method of the heat conduction plate of the plate heat exchanger in detail. I hope that through this article, it will be helpful for you to understand the heat transfer plate of the plate heat exchanger.

Finally, if you have the need for procurement, you are welcome to visit our marine heat exchanger homepage or contact us at any time! Thank you again for your browsing!