CPL-190 Marine Vertical Type Liquid Magnetic Compass

Overview

Certification: CCS approval.

Features

Precision Navigation: Engineered for pinpoint accuracy, provide reliable heading information.

Night Navigation Capability: Equipped with efficient lighting, ensures clear visibility of dial divisions during nighttime.

Water-Resistant Construction: Designed to withstand marine environments.

Sensor Integration for Automation: With water-tight glass and positioning blocks, the compass allows easy integration of sensors, enabling seamless connectivity to automatic operation instruments.

Main technical data

Card diameter: ф190mm

Card Graduation: 0~360° , 1°per graduation

Operating temperature: -30℃~+60℃

Direction error: ≤0.5°

Swinging semi-period: ≥8.27S

Friction error: ≤0.08°

The main semicircular deviation correction of energy: 1°~45°

A semicircular deviation correction of energy: 1°~6°

Quadrant deviation correction: 0.5°~10°

Heeling error correction:-75~+75µΤ

Illumination: AC220V, DC24V

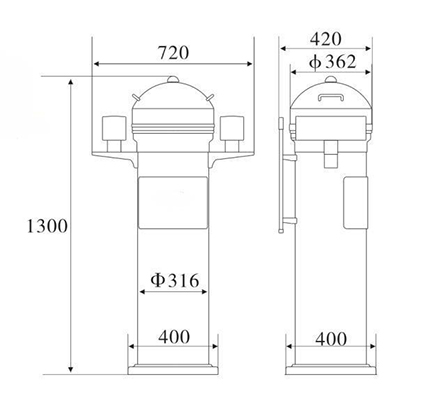

Overall dimensions: 720×400×1300mm

Carton size: 800×540×1490 mm

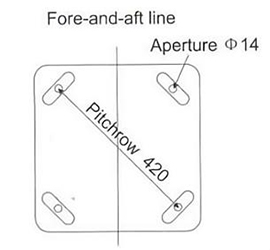

Installation dimensions: pitchrow420; aperture ф14

Net weight: about 42Kg

Outline dimension

Base installation size

Why Choose CPL-190?

Reliable and Accurate Navigation

Sturdy Vertical Type Design

Enhanced Night Navigation

Self deviation correcting system

Sensor-Ready for Automation

Installation & maintenance

The standard compass is usually installed on the upper deck, where the view is good and not blocked. It is reliably fixed with 4 bolts and nuts, and the bow and stern lines of the basin coincide or are parallel, which can be adjusted by 4-long round holes on the compass seat.

In order to ensure the accuracy of the compass, any magnetic objects, such as steel components, DC motors, cables, etc. should be far away from the compass, and its safety distance (magnetic radius) is 1.5 meters.

When installing the compass, its height should be suitable for the requirements of the observer, the hard wood can be used for low height, and the wooden platform can be added around the compass when it is too high.

After correcting the deviation of the compass can not be arbitrarily changed, corrected position and magnetic rod. The number of adjustment pieces, etc., should be recorded. (Tighten various caps)

Unused correction magnets, soft iron rods, adjusting plates, etc. should be put back into the spare parts box, and there should be no magnetic materials to move around the compass.

Do not remove the pot when it is not necessary, and cover the canvas cover when the compass is not needed.

Pay attention to the cleanliness of the compass, especially do not let the sea water, dust, oil accumulation, the rotating part, can be appropriate to apply some grease or lubricating oil.