Cast Iron Globe Valves JIS

Cast Iron Globe Valves is commonly used in piping systems to regulate the flow of liquids or gases. It is known for its durability and reliable performance in both open and closed positions, as well as for throttling applications. The valve's design includes a movable disc (or globe) that, when rotated, either blocks or allows flow through the valve body.

Overview

Key features:

Material: Made of cast iron, providing strength, durability, and resistance to corrosion, making it suitable for marine environments and applications involving non-corrosive fluids.

Design: Typically, these valves have a rising or non-rising stem, with various options for handwheel operation, and come in a flanged or threaded configuration.

Flow Control: Designed to regulate flow, Cast Iron Globe Valves offer good throttling capabilities, making them ideal for applications requiring precise flow control.

Disc Options: The valve discs are usually made of resilient materials or metals to ensure reliable sealing and minimize leakage.

Seat: The seats are designed for a secure shutoff, often bolted or threaded for easy maintenance and replacement, with materials like stainless steel or brass to increase longevity.

Pressure and Temperature Ratings: Typically used in low- to medium-pressure systems, with temperature and pressure ratings suited to the specific valve model.

Maintenance: Cast iron globe valves are relatively low-maintenance and provide easy access for repairs, making them convenient in operational settings where servicing is required.

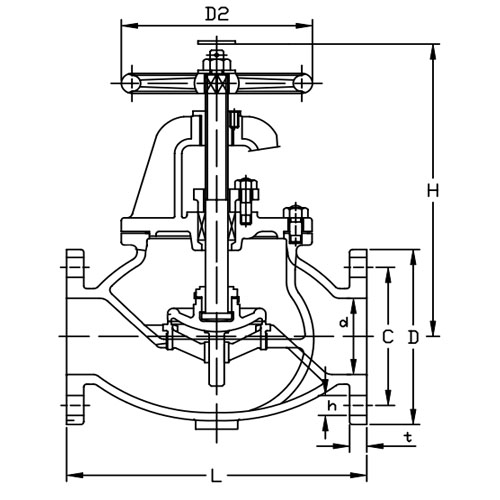

Drawing:

Image of product:

MAIN DIMENSIONS | |||||||||

Size | L | D | C | No. | h | t | H | D2 | Kg |

50 | 210 | 130 | 105 | 4 | 15 | 16 | 270 | 160 | 14.7 |

65 | 250 | 155 | 130 | 4 | 15 | 18 | 300 | 180 | 21.3 |

80 | 280 | 180 | 145 | 4 | 19 | 18 | 310 | 180 | 27.7 |

100 | 340 | 200 | 165 | 8 | 19 | 20 | 360 | 224 | 40.8 |

125 | 410 | 235 | 200 | 8 | 19 | 20 | 390 | 250 | 57.6 |

150 | 480 | 265 | 230 | 8 | 19 | 22 | 445 | 280 | 80.3 |

200 | 570 | 320 | 280 | 8 | 23 | 24 | 530 | 315 | 139 |

250 | 740 | 385 | 345 | 12 | 23 | 26 | 650 | 355 | 216 |

300 | 840 | 430 | 390 | 12 | 23 | 28 | 740 | 400 | 346 |

350 | 940 | 480 | 435 | 12 | 25 | 30 | 840 | 500 | 418 |

400 | 1050 | 540 | 495 | 16 | 25 | 30 | 940 | 630 | 600 |