Carbon Steel Safety Valve

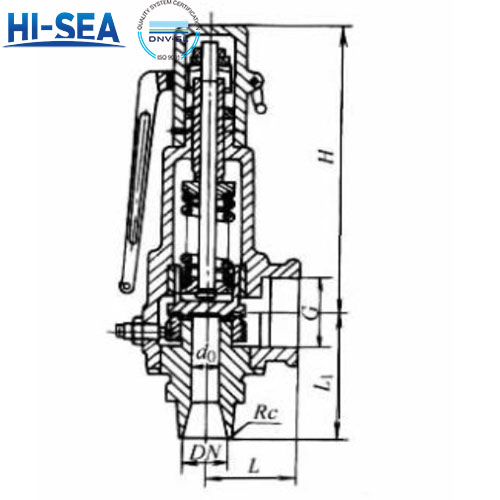

Carbon steel safety valves: DN6-DN125;

Pressure adjustment range: 0-2.5Mpa;

Application: water treatment, laboratories, corrosive liquids, common gases;

Adjustable pressure 0-1.0MPa, 0-2.0MPa, 0-3.0 Mpa;

Safety test pressure: 1.5 times the maximum input pressure; Applicable temperature: ordinary diaphragm -5℃ to +80℃); PTFE diaphragm: -5℃ to +80℃).

Overview

Safety valves installation is correct or not, not only related to the safety valve can work properly and play its due role, but also will directly affect the safety valve action performance, sealing performance and displacement and other indicators.

Installation position:

1. Safety valves on equipment or piping are installed vertically.

2. Generally installed close to the protected equipment in a location that is easy to maintain and inspect.

3. Steam safety valves are installed in the highest position of the boiler's cylinder or header tank, or in the highest position of the gas phase space above the liquid level of the equipment being protected.

4. Liquid safety valves are installed below the normal liquid level.

Drawing:

Picture: