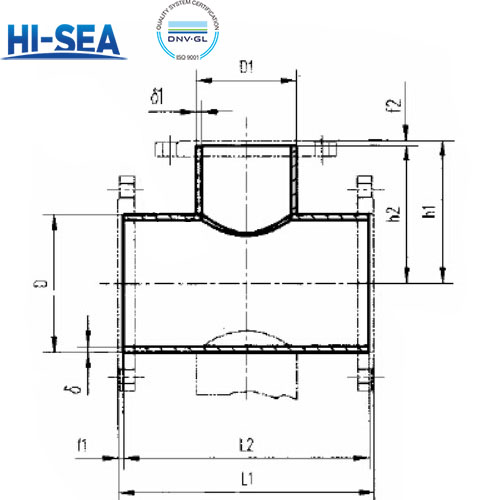

Butt Welding Reducer Tee

Butt-welding reducer tee is a kind of pipeline connector, connected to the pipe by welding, able to connect different diameters of the pipeline, with a solid connection, good sealing characteristics, suitable for pipeline systems that need to withstand high pressure, high temperature or corrosive media.

Overview

Characteristics

Caliber change: Butt-welding reducer tee allows connection between pipes of different diameters, realizing the transition from a large-diameter pipe to a small-diameter pipe.

Connection: mainly connected by welding, suitable for high pressure and high temperature working conditions.

Various materials: can be made of various materials, such as carbon steel, stainless steel, etc., with good corrosion resistance and pressure resistance.

Widely used: widely used in the piping system of petrochemical, natural gas, water treatment and other industries.

Advantages

Simple structure

Corrosion resistance

Good sealing performance

High temperature resistance

Wear-resistant

Wide range of applications

High strength

Outside diameter of pipe | EEMUA 146 | ||||||||||||||

16Bar | 20Bar | ||||||||||||||

θDxθd | θDxθd | Wall | Centre | Theoretical | Wall | Centre | Theoretical | ||||||||

thickness | to face | weight | thickness | to face | weight | ||||||||||

nominal | actual | E | e | A | C | Kg/ piece | E | e | A | C | Kg/ piece | ||||

inch | mm | mm | mm | mm | mm | mm | mm | mm | mm | ||||||

10 | x | 4 | 267 | x | 108 | 4.5 | 3 | 216 | 184 | 21.6 | 5.5 | 3 | 216 | 184 | 26.4 |

10 | x | 6 | 267 | x | 159 | 4.5 | 3 | 216 | 194 | 21.75 | 5.5 | 3.5 | 216 | 194 | 26.6 |

10 | x | 8 | 267 | x | 219.1 | 4.5 | 4 | 216 | 203 | 21.9 | 5.5 | 4.5 | 216 | 203 | 26.75 |

12 | x | 6 | 323.9 | x | 159 | 5.5 | 3 | 254 | 219 | 38.5 | 7 | 3.5 | 254 | 219 | 49 |

12 | x | 8 | 323.9 | x | 219.1 | 5.5 | 4 | 254 | 229 | 39.6 | 7 | 4.5 | 254 | 229 | 50.4 |

12 | x | 10 | 323.9 | x | 267 | 5.5 | 4.5 | 254 | 241 | 40.7 | 7 | 5.5 | 254 | 241 | 51.8 |

14 | x | 8 | 368 | x | 219.1 | 6.5 | 4 | 279 | 248 | 58.8 | 8 | 4.5 | 279 | 248 | 72.35 |

14 | x | 10 | 368 | x | 267 | 6.5 | 4.5 | 279 | 257 | 59.7 | 8 | 5.5 | 279 | 257 | 73.5 |

14 | x | 12 | 368 | x | 323.9 | 6.5 | 5.5 | 279 | 270 | 61.5 | 8 | 7 | 279 | 270 | 75.7 |

16 | x | 10 | 419.1 | x | 267 | 7 | 4.5 | 305 | 283 | 89.6 | 9 | 5.5 | 305 | 283 | 115.2 |

16 | x | 12 | 419.1 | x | 323.9 | 7 | 5.5 | 305 | 295 | 91.4 | 9 | 7 | 305 | 295 | 117.5 |

16 | x | 14 | 419.1 | x | 368 | 7 | 6.5 | 305 | 305 | 93.5 | 9 | 8 | 305 | 305 | 120.2 |

18 | x | 12 | 457.2 | x | 323.9 | 8 | 5.5 | 343 | 321 | 126.3 | 9.5 | 7 | 343 | 321 | 150 |

18 | x | 14 | 457.2 | x | 368 | 8 | 6.5 | 343 | 330 | 128.3 | 9.5 | 8 | 343 | 330 | 152.35 |

18 | x | 16 | 457.2 | x | 419.1 | 8 | 7 | 343 | 330 | 129.9 | 9.5 | 9 | 343 | 330 | 154.25 |

20 | x | 14 | 508 | x | 368 | 8.5 | 6.5 | 381 | 356 | 162 | 11 | 8 | 381 | 356 | 209.65 |

20 | x | 16 | 508 | x | 419.1 | 8.5 | 7 | 381 | 356 | 164.2 | 11 | 9 | 381 | 356 | 212.5 |

20 | x | 18 | 508 | x | 457.2 | 8.5 | 8 | 381 | 368 | 168.3 | 11 | 9.5 | 381 | 368 | 217.8 |

24 | x | 16 | 610 | x | 419.1 | 10.5 | 7 | 432 | 406 | 248.3 | 13 | 9 | 432 | 406 | 307.4 |

24 | x | 18 | 610 | x | 457.2 | 10.5 | 8 | 432 | 419 | 251.7 | 13 | 9.5 | 432 | 419 | 311.6 |

24 | x | 20 | 610 | x | 508 | 10.5 | 8.5 | 432 | 432 | 255.3 | 13 | 11 | 432 | 432 | 316.1 |

28 | x | 18 | 711 | x | 457.2 | 12 | 8 | 521 | 470 | 394.6 | 15 | 9.5 | 521 | 470 | 493.25 |

28 | x | 20 | 711 | x | 508 | 12 | 8.5 | 521 | 483 | 398.2 | 15 | 11 | 521 | 483 | 497.75 |

28 | x | 24 | 711 | x | 610 | 12 | 10.5 | 521 | 508 | 409.9 | 15 | 13 | 521 | 508 | 512.4 |

32 | x | 20 | 813 | x | 508 | 13.5 | 8.5 | 597 | 533 | 495 | 17 | 11 | 597 | 533 | 623.3 |

32 | x | 24 | 813 | x | 610 | 13.5 | 10.5 | 597 | 559 | 506.8 | 17 | 13 | 597 | 559 | 638.2 |

32 | x | 28 | 813 | x | 711 | 13.5 | 12 | 597 | 572 | 518.8 | 17 | 15 | 597 | 572 | 653.3 |

36 | x | 24 | 914 | x | 610 | 15.5 | 10.5 | 673 | 610 | 723.6 | 19 | 13 | 673 | 610 | 887 |

36 | x | 28 | 914 | x | 711 | 15.5 | 12 | 673 | 622 | 735.4 | 19 | 15 | 673 | 622 | 901.45 |

36 | x | 32 | 914 | x | 813 | 15.5 | 13.5 | 673 | 648 | 754.4 | 19 | 17 | 673 | 648 | 924.75 |