Bilge Water Injection System for Incinerators

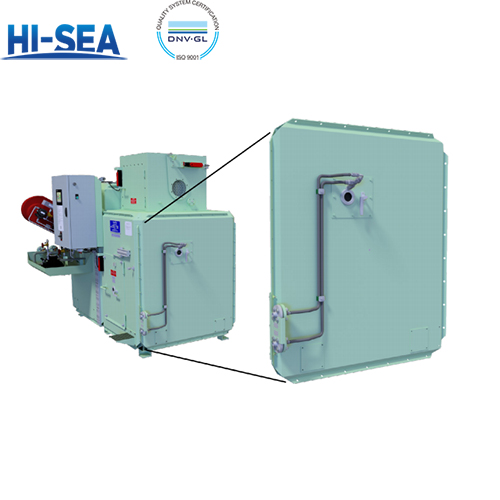

Bilge Water Injection System for Incinerators consists of a bilge water injector, a bilge water service cabinet, a control system (included in the main electrical control box), etc.

The bilge water service cabinet is equipped with a single screw pump, high and low liquid level float balls, and a heating system (steam or electricity or hot oil). The high and low liquid level signal float balls control the start and stop of the bilge water transfer pump. When the furnace temperature reaches above 1000°C and if the incinerator is incinerating dirty oil, the bilge water injection incineration system can be started.

If you have demands or questions about incinerators, please contact us at the email address <hs10@cqhisea.com>!

Overview

Purpose and Benefits

Supplement to the OWS

Developed primarily for disposal of bilge water

Reduced NOx emission

Increased sludge burning capacity

Inexpensive

IMO certified

No filters or strainers

No chemicals

Quick and simple upgrading of existing incinerators

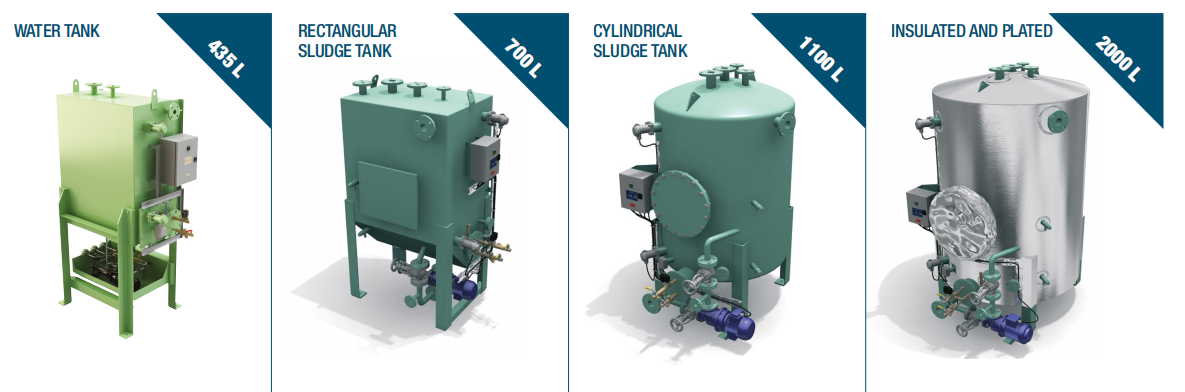

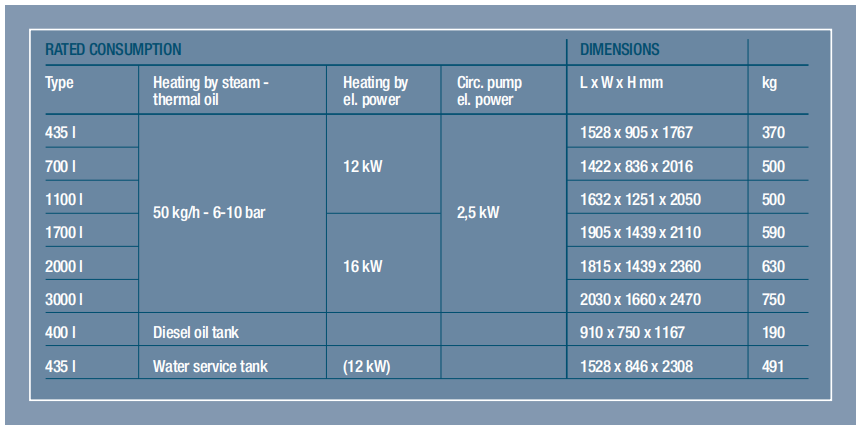

Sludge Preparation Tank

In order to achieve the best economic operation and the highest efficiency for any incinerator, we recommend installing two cylindrical sludge tanks for proper water sedimentation and drainage. One tank is for sedimentation and the other is a service tank. All series of storage tanks are equipped with sludge circulation pumps, liquid level switches and thermostats.

Adding the sludge heating/mixing tank device to the marine incinerator system has the following several important functions:

Improve incineration efficiency: Heating the sludge can reduce its viscosity, making it easier to flow and burn, thereby improving the processing efficiency of the incinerator.

Promote uniform combustion: Through the mixing effect, different components in the sludge can be fully mixed to ensure more uniform combustion during the incineration process and reduce incomplete combustion.

Enhance combustion stability: Making the physical and chemical properties of the sludge more uniform helps maintain stable combustion conditions and reduces combustion fluctuations and abnormal situations.

Pretreat the sludge: Before entering the incinerator, proper heating and mixing of the sludge can remove some of the moisture, reduce the energy required during incineration, and at the same time reduce the thermal shock to the incinerator.

Optimize the combustion quality: It helps to expose and decompose the organic matter in the sludge more fully, thereby improving the combustion quality and reducing the emissions of harmful gases and pollutants.

In conclusion, the sludge heating/mixing tank device can enhance the performance of the marine incinerator, improve the ability and effect of treating the sludge, and at the same time help meet environmental protection requirements.

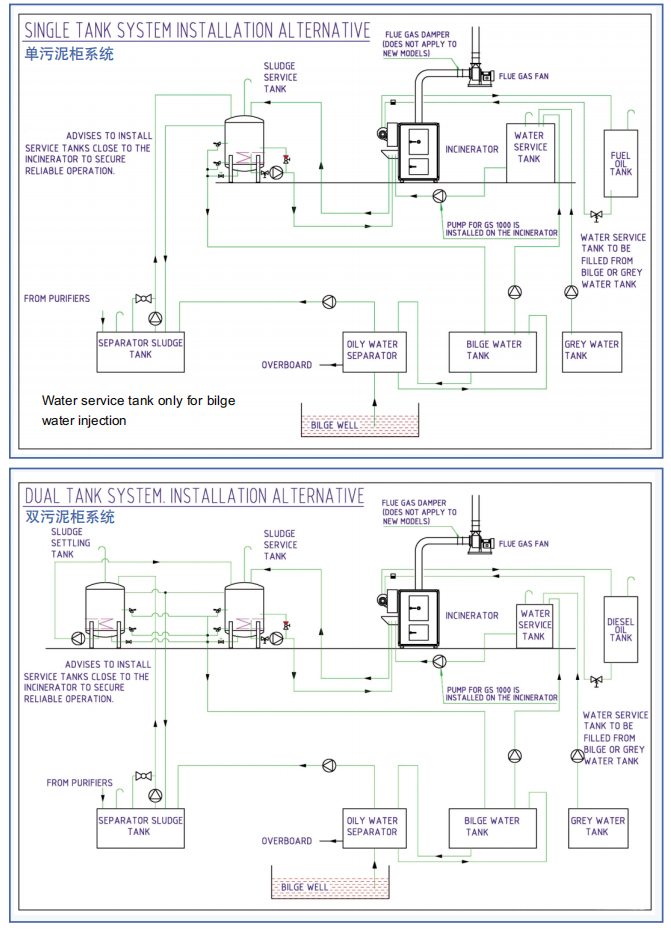

Recommended Installation Method of the Ship's Incinerator

Conclusion

Thank you for browsing this webpage. We believe you have gained a preliminary understanding of Bilge Water Injection System for Incinerators. If you have relevant purchasing needs, you are welcome to visit the homepage of our incinerator or contact us directly by email!