Alloy Steel Pipe

Alloy steel pipe is mainly used in power plants, nuclear power, high-pressure boilers, high-temperature super heater and reheater and other high-pressure and high-temperature pipeline and equipment, it is the use of high-quality carbon steel, alloy structural steel and stainless heat-resistant steel to do the material, by hot-rolled (extrusion, expansion) or cold-rolled (drawn) and become. Alloy pipe chemical composition contains more Cr, high temperature resistance, low temperature resistance, corrosion resistance properties.

Overview

Application:

Alloy steel pipe has a hollow cross-section and is used in large quantities as a pipeline for the transportation of fluids, such as pipelines for the transportation of oil, natural gas, gas, water and certain solid materials.

Compared with solid steel such as round steel, alloy steel pipe is lighter in weight when the bending and torsion strength is the same. Alloy steel pipe is a kind of economic cross-section steel, which is widely used in the manufacture of structural and mechanical parts, such as petroleum drilling rods, automobile driveshafts, bicycle frames, and steel scaffolding used in building construction.

Alloy steel pipe can be divided into round pipe and shaped pipe according to the different shape of cross-sectional area. Since the circular area is the largest under the condition of equal perimeter, more fluid can be transported with circular pipe. In addition, the circular cross-section is more uniformly stressed when subjected to internal or external radial pressure, therefore, the vast majority of steel tubes are round tubes.

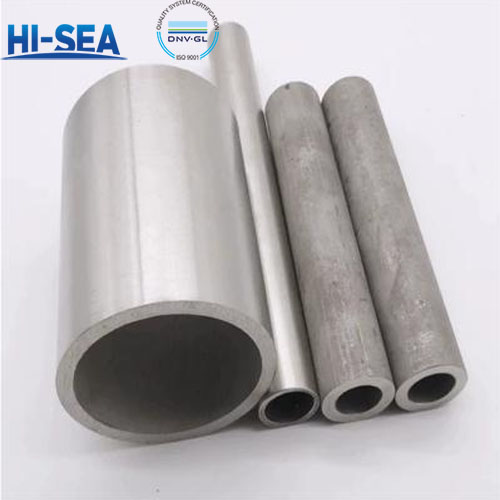

Picture: