White metal stern tube bearing and its inspection

White metal bearings are mainly used on ships with various types of oil lubrication media. White metal bearings are developed on the basis of copper bearings. The inner surface of the white metal bearing liner is made of several longitudinal and transverse dovetail grooves and is cast with white metal. White metal bearings can be divided into stern tube front bearings and stern tube rear bearings.

Overview

White metal stern tube bearings are mainly used on ships with various types of oil lubricating media. The shell material can be selected from copper alloy, cast iron, or cast steel according to customer requirements. White metal bearings have good wear resistance and wear reduction performance; Has a certain compressive strength and hardness, and sufficient fatigue strength and bearing capacity; Good plasticity and impact toughness; Has good anti bite properties; Good compliance; Good inlay performance; It should have good thermal conductivity, corrosion resistance, and a small coefficient of thermal expansion. This type of bearing is currently widely used on various types of ships.

For more marine metal stern tube bearing information, kindly please click here.

For more marine shaft system components, kindly please click here.

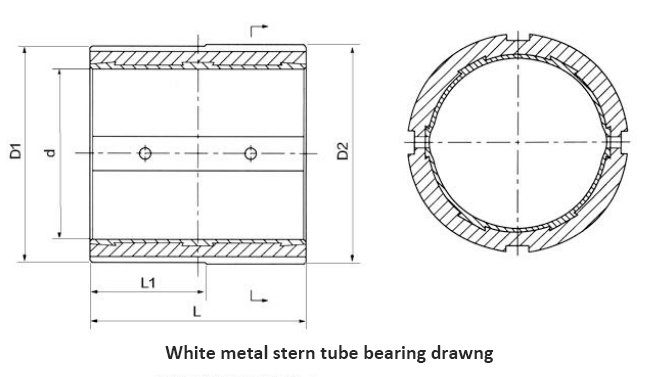

White metal stern tube bearing drawing

White metal stern tube bearing inspection

(1) Before installing the stern tube bearings, cleaning and inspection should be carried out. Any remaining iron shavings, burrs, molding sand, welding slag, oil stains, and other residues and garbage inside the stern tube should be removed thoroughly; Retest the outer diameter of the front and rear bearings of the stern tube and the inner hole of the stern tube.

(2) Bearing press fit inspection shows that the bearing is in an interference fit with the stern shaft tube. Hydraulic stretchers are commonly used to press the bearing into the boat shaft tube during bearing installation. During the pressing process, the hydraulic pressure and pressing distance should be recorded for every 50mm of pressing. The final pressure should meet the design requirements. If there are no design requirements, the values in the table below can be referred to. When pressing in the bearing, it is necessary to carefully check the "TOP" mark on the bearing, so that the part marked with "TOP" is facing upwards.

Installation pressure of stern tube bearings

Name | Bearing outer diameter D | Pressing force/kN | |

Forward bearings | After bearings | ||

Pressure lubrication Stern tube bearings | 300<D<500 | 68.65~294.2 | 147.1~588.4 |

500<D<900 | 147.1~588.4 | 343.23~980.67 | |

900<D | 147.1~784.53 | 343.23~1176.8 | |