What is the plane frictional watertight rudder carriers

Suitable for large and medium-sized ships with a rudder stock diameter of over 200mm.

Plane frictional watertight rudder carriers are a special component used in ship rudder systems, primarily designed to support and rotate the rudder stock while ensuring the system's water tightness and preventing seawater from infiltrating the interior of the ship.

The rotation of the rudder stock is achieved through the relative motion of the planar friction plate on a plane frictional watertight rudder carriers.

Overview

When the rudder stock rotates, the frictional force between the flat friction plates provides the necessary support. At the same time, the sealing device ensures water tightness and prevents seawater from seeping into the interior of the ship. Suitable for large and medium-sized ships with a rudder stock diameter of over 200mm.

For more marine rudder system components, kindly please click here.

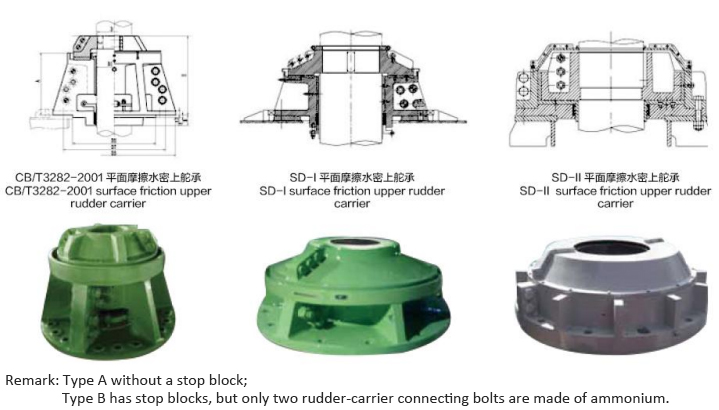

Type and structure of the plane frictional watertight rudder carriers

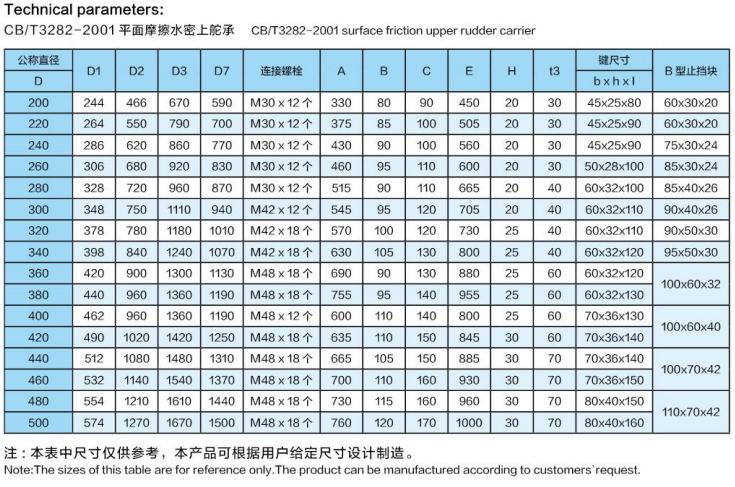

Technical parameters of the plane frictional watertight rudder carriers

Requirements of the plane frictional watertight rudder carriers

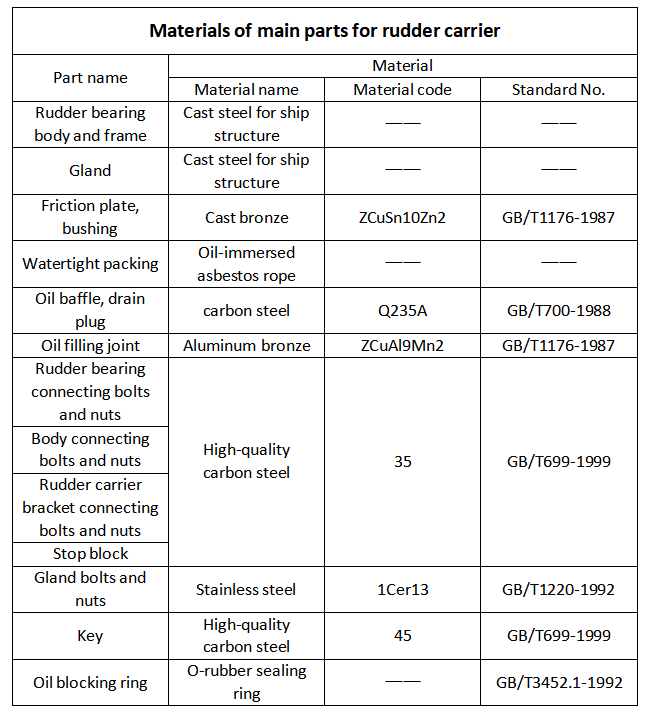

1. Materials of main parts for rudder carrier

2. Steel castings should not have shrinkage, porosity, cold shut, cracks, or other defects that affect strength. For surface defects that do not affect strength, welding repair is allowed, but it must comply with the repair requirements of relevant standards and specifications for defects in steel castings. All castings should be annealed or normalized.

3. The surface of the parts should be smooth and free from cracks, burrs, spots, and other appearance defects.

4. The contact surface between the two halves of the rudder bearing body should be scraped flat, and there should be no oil leakage after connecting the two halves with bolts After the assembly of the upper rudder bearing is completed, the pointer on the wear indicator should be pointed to the zero position.

When the upper rudder bearing is automatically lubricated by a lubricating oil pump, the oil cup can be removed and replaced with an oil pipe joint at that position. After passing the inspection of the upper rudder bearing, the outer surface should be manually rust removed and coated with 2 coats of anti rust primer.