What is Shell and Tube Heat Exchanger

Marine shell and tube heat exchangers are the types of partition wall heat exchangers with the wall surface of the tube bundle enclosed in the shell as the heat transfer surface. It is composed of a set of tube bundles or coils installed in a shell. The two media that transfer heat, one is in the tube and the other is in the shell outside the tube, and the heat is transferred through the tube wall. This kind of heat exchanger has a relatively simple structure, reliable operation, and can be manufactured with various structural materials (mainly metallic materials) and can be used under high temperature and high pressure, and it is the most widely used type at present.

Overview

Structure

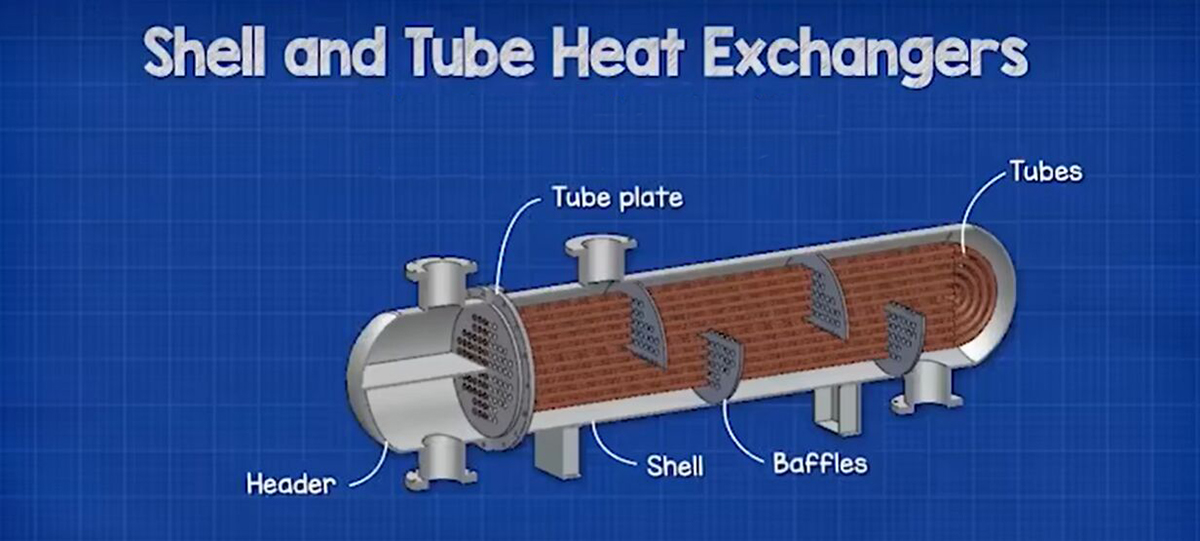

The shell and tube heat exchanger mainly has the following structures:

Shell: It is a container that accommodates the tube bundle and other components.

Tube bundle: Composed of multiple tubes, it is the main part for heat exchange, and fluids of different temperatures flow inside and outside the tube respectively.

Tube sheet: Fixes the tube bundle and separates the shell and the tube bundle space.

Head: Located at both ends of the shell, used to seal the shell.

Baffle plate or baffle: Set in the shell to guide the fluid flow, increase the turbulence degree of the fluid, and improve the heat exchange efficiency.

Inlet and outlet nozzles: Used for the inflow and outflow of fluids.

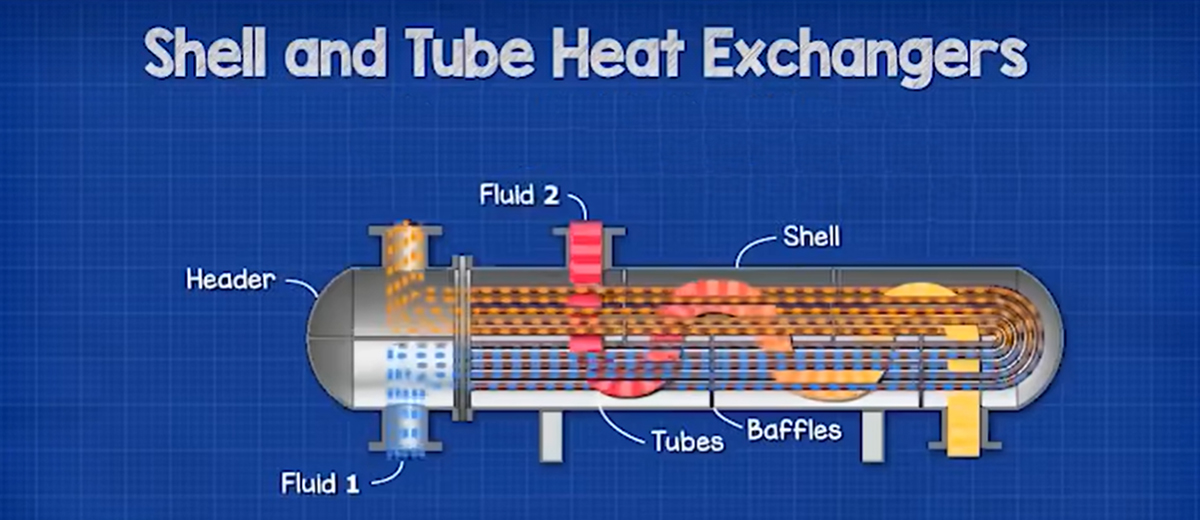

For example, in some industrial cooling systems, the high-temperature fluid enters the tube bundle from the inlet at one end of the heat exchanger, and the low-temperature fluid enters the shell side from the inlet on the shell, and exchanges heat with the high-temperature fluid in the tube through the tube wall. After completing the heat exchange, it flows out from their respective outlets. In this process, each structural part of the shell and tube heat exchanger works together to ensure the stability and efficient progress of the heat exchange process.

Principles

The working principle of the shell and tube heat exchanger involves the synergistic effect of multiple heat transfer mechanisms.

Firstly, heat conduction plays a key role therein. When a fluid with a relatively high temperature flows in the tube bundle, the heat in the fluid will gradually be conducted to the tube wall in direct contact with the fluid through the collision and interaction between molecules. The tube wall material usually has good thermal conductivity and can effectively transfer the heat from the fluid in the tube to the surface of the tube wall.

At the same time, convective heat transfer is also indispensable. During the flowing process of the fluid in the tube, due to the viscosity and flow characteristics of the fluid, a boundary layer will be formed near the tube wall. In this boundary layer, the flow velocity of the fluid is relatively slow, and the heat is mainly transferred through the conduction mode; while outside the boundary layer, the flow velocity of the fluid is relatively fast, and the heat is mainly transferred through the convective mode. Through convection, the hot fluid continuously transfers the heat to the fluid layer near the tube wall, causing its temperature to rise.

In the shell side, the cold fluid also exchanges heat with the tube wall outside the tube bundle. The cold fluid absorbs heat from the tube wall through convective heat transfer, and its temperature gradually rises.

The tube wall, as a medium of heat transfer, transfers the heat of the hot fluid in the tube to the cold fluid outside the tube. In this process, the heat is transferred from the side with a high temperature to the side with a low temperature, following the second law of thermodynamics.

In order to further improve the heat exchange efficiency, baffle plates or baffles are set in the shell and tube heat exchanger. These baffle plates or baffles will force the fluid in the shell side to change the flow direction and increase the degree of turbulence of the fluid. The increase in turbulence makes the contact between the fluid and the tube wall more sufficient, reduces the thickness of the thermal boundary layer, and thus enhances the convective heat exchange effect. At the same time, the turbulence of the fluid is also beneficial to the uniform distribution of heat in the fluid and improves the overall heat exchange performance.

Conclusion:

The above is the entire content of this article. In the article, we have detailedly introduced to you the basic structure and principles of the shell and tube heat exchanger. We hope that through this article, it can help you choose the shell and tube heat exchanger.

Finally, if you have the need for procurement, you are welcome to visit our marine heat exchanger homepage or contact us at any time! Thank you again for your browsing!