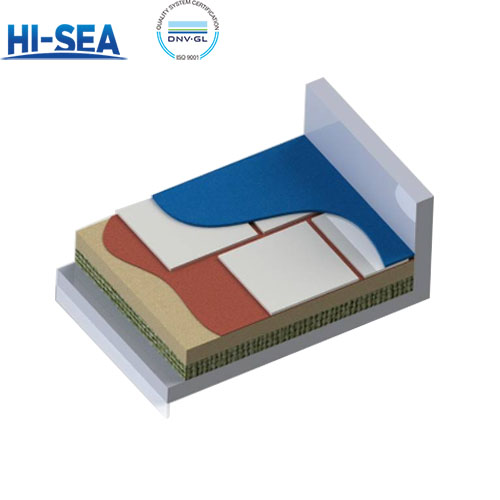

What is Marine Floating Floor

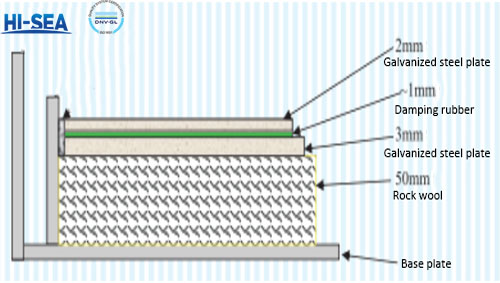

Floating floor is made of 50mm lightweight fire insulation material rock wool as the bottom layer, the upper layer in turn laying 3mm and 2mm thick galvanized steel plate (the middle of the use of 1mm thick damping adhesive bonding) combined into a floating deck structure. It is mainly used for local (A60 fireproof requirements) cabins of ships, with excellent vibration damping, noise reduction, sound insulation and heat insulation functions.

Overview

Feature:

1. Excellent vibration damping, noise reduction, sound insulation, heat insulation and acoustic function, after testing, the sound insulation value of 62db.

2. Light weight, effectively reduce the empty ship tonnage.

3. The overall thickness of the product is thin, effectively increasing the interior space.

4. Fire resistance class reaches A60.

5. It can effectively improve the comfort of cabin crew.

Structure:

Flooring

Metallic restraining layer

Damping layer

Rock wool layer

(Deck dressing)

Steel Plate Deck

Picture:

Item | Testing | Unit | Standard | Actual value |

1 | Damping layer composite loss factor | nc | ≥0.1 | 0.25 |

2 | Sound insulation level | R45db | 62db | |

3 | Fire Class | A60 | A60 | |

4 | Rock wool capacity | kg/m³ | 140 | 140 |

5 | Surface density | kg/m² | 47.2 | 47.2 |

6 | Total Thickness | mm | 56 | 56 |

7 | Drying time | H | 12~18 time | 15 |