What is Marine Bottom Plug Spanner?

The Marine bottom plug spanner is a special tool for rotating the bottom plug to achieve installation, removal or tightening operations. It is specially designed according to the shape, size and thread specification of the bottom plug. It is convenient for the user to apply the torque and complete the related operation of the bottom plug. Make sure the bottom plugs are in place and maintain a good seal. It also makes the installation and disassembly of the bottom plug easier and more efficient.

Overview

Working Principle

1. Lever principle: Increase the torque acting on the bottom plug through the length or shape of the spanner.

2. Gear or rack drive: Some wrenches use a gear or rack structure to convert manually applied forces into greater torque.

3. Fit design: The shape of the spanner matches the interface of the bottom plug to ensure the effective transmission of torque.

4. Anti-slip design: Increase the friction between the wrench and the bottom plug to prevent slipping.

When using the bottom plug spanner, the operator makes the wrench turn by applying force, thus driving the bottom plug to rotate. The amount of torque depends on the force applied by the operator and the design of the spanner. The right spanner provides enough torque to smoothly complete the operation of the bottom plug. At the same time, the correct use of spanners can also avoid damage to the bottom plug and surrounding components.

Material

The material of the bottom plug spanner is generally steel and carbon steel galvanized. The steel bottom plug spanner has high strength and durability and is suitable for most Marine environments. The bottom plug spanner of galvanized carbon steel is added with galvanized layer on the basis of steel, so that it has better corrosion resistance, and is suitable for wet and corrosive ship environment.

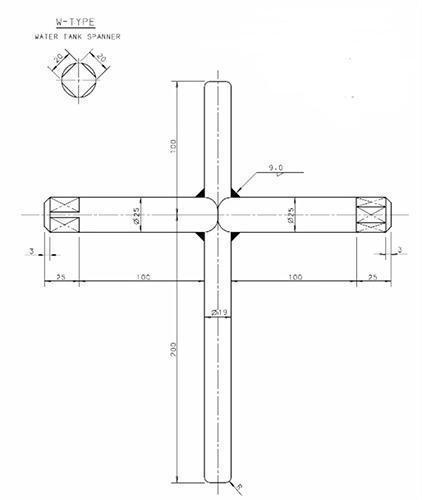

Drawing

Images of Marine Bottom Plug Spanner