What is a marine stern shaft lubrication oil tank?

The marine stern shaft lubrication oil tank is a key component in the ship's power transmission system.

Its main function is to provide lubricating oil to the propeller shaft of the ship, ensuring smooth operation of the shaft during rotation, reducing friction and wear.

Overview

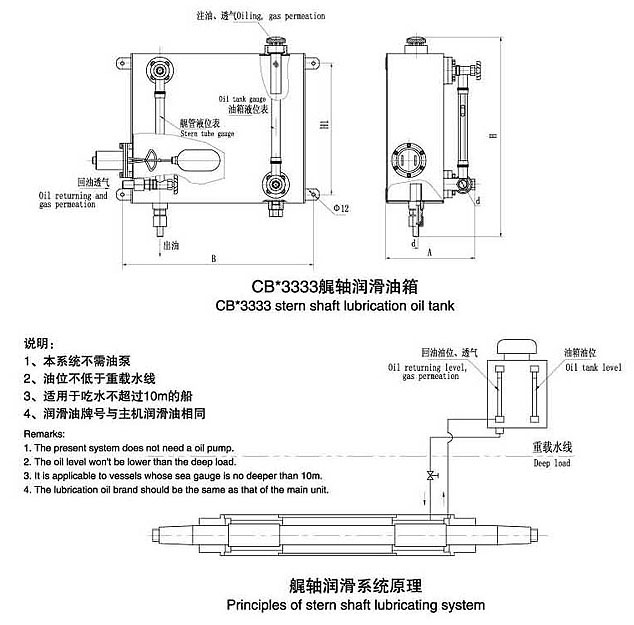

The stern shaft lubrication oil tank is an important component of the ship's stern shaft system, used for storing and supplying lubricating oil to ensure lubrication of the stern shaft and bearings, thereby reducing friction and wear. The design and maintenance of the stern lubrication oil tank are crucial for the normal operation of ships. The marine stern shaft lubrication oil tank mainly consists of a box body, a cover, a funnel with a filter screen, an oil tank level gauge, a breathable level gauge, etc.

Major function

Lubrication function: The lubricating oil stored in the lubricating oil tank is transported to the stern shaft and its related bearing parts through the pipeline system, forming a lubricating film, reducing direct metal contact between the bearings and the stern shaft, thereby reducing friction and wear.

Cooling effect: While lubricating, lubricating oil also plays a role in taking away the heat generated by friction, helping to maintain the temperature of the stern shaft system within a safe range and prevent overheating.

Anti corrosion effect: Lubricating oil also has anti-corrosion function, which can prevent seawater or other corrosive substances from corroding the stern shaft and bearings, and extend the service life of the equipment.

For more stern shaft lubrication oil tank information, kindly please click here.

For more marine shaft system components, kindly please click here.

Main structure

Technical requirement

1. When installing the fuel tank on the ship, its bottom should be 500-1000mm higher than the ship's full load waterline. If installation is difficult, the height of the fuel tank can be appropriately lowered, but its bottom cannot be lower than the ship's full load waterline.

2. For oil lubricated tail shafts with a basic diameter greater than 120mm, each tail shaft is equipped with a fuel tank. Two fuel tanks can be connected, but a shut-off valve must be installed on the connecting pipe.

3. The tail shaft lubricating oil adopts the same grade of engine oil as the main engine lubricating oil.

4. The fuel tank supplies oil to the tailpipe by gravity, without the need for an oil pump.

5. The box cover has a breathable function and there is no need to install a ventilation pipe.

6. Apply one coat of red lead on both the inner and outer surfaces of the fuel tank, and then apply one coat of paint of the same color as the cabin.

7. According to usage requirements, a low oil level alarm device can be installed.

Test method

Each oil tank should undergo a tightness test at atmospheric pressure by the manufacturer to ensure no leakage.

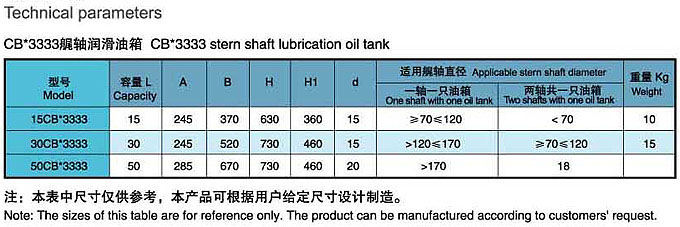

Main technical parameter