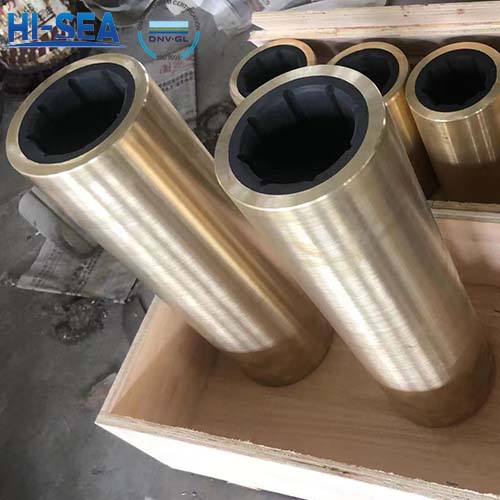

What is a marine integral/whole rubber bearing

Marine integral rubber bearings are a key component specifically designed for ship propulsion systems. It is usually installed in the stern pipe system of ships to support the ship's shaft and ensure its smooth operation. The working medium of the stern tube of the ship is water, and it is recommended to use rubber bearings instead.

Overview

Marine integral rubber bearings are a key component specifically designed for ship propulsion systems. It is usually installed in the stern pipe system of ships to support the ship's shaft and ensure its smooth operation. The working medium of the stern tube of the ship is water, and it is recommended to use rubber bearings instead.

For more marine integral rubber bearing information, kindly please click here.

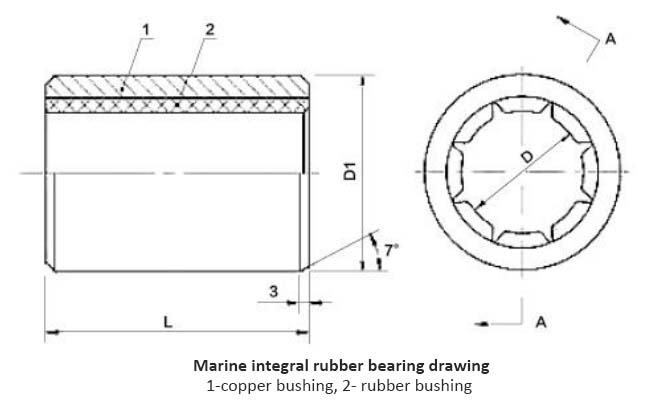

Marine integral rubber bearing drawing

Main technical parameters

Quality requirement

Sealing performance of rubber bearing outer sleeve

Before pouring rubber, a water pressure test should be conducted on the outer sleeve of the rubber bearing, with a pressure of 0.15MPa and a holding time of 10 minutes without any leakage.

Surface quality of rubber bearings

The rubber surface has no layering, cracks, impurities, bubbles, or peeling;

The longitudinal grooves of the rubber part should be evenly distributed and parallel;

The two ends of the surface should have no concavity or convexity;

The rubber working surface has no repair.

Environmental adaptability

Rubber bearings should be able to be stored and operated under the environmental.

Conditions specified in the table below without damage

Storage and working environment of rubber bearings | ||

Environment condition | Storage | Working |

Minimum ambient temperature | -10℃ | 0℃ |

Maximum ambient temperature | 30℃ | 60℃ |

Relative humidity | ≤80% | —— |

Salt spray effect | 1mg/m3 | —— |

Fungal effects | Class 1 | —— |