What Is A Gear Pump?

Gear pump is a rotary pump that relies on the working volume change and movement formed between the pump cylinder and the engaging gear to transport liquid or pressurize it. Marine gear pump has KCB series Marine gear oil pump, 2CY series Marine gear oil pump and YCB series Marine gear oil pump.

Overview

Working principle

Through the rotation of the gear to transport the liquid or make the liquid pressurization, by the two gears, the pump body and the front and back cover composed of two closed Spaces, when the gear rotates, the volume of the space on the side of the gear off from small to large, forming a vacuum, the liquid inhalation, the volume of the space on the gear meshing side from large to small, to achieve the purpose of liquid transmission.

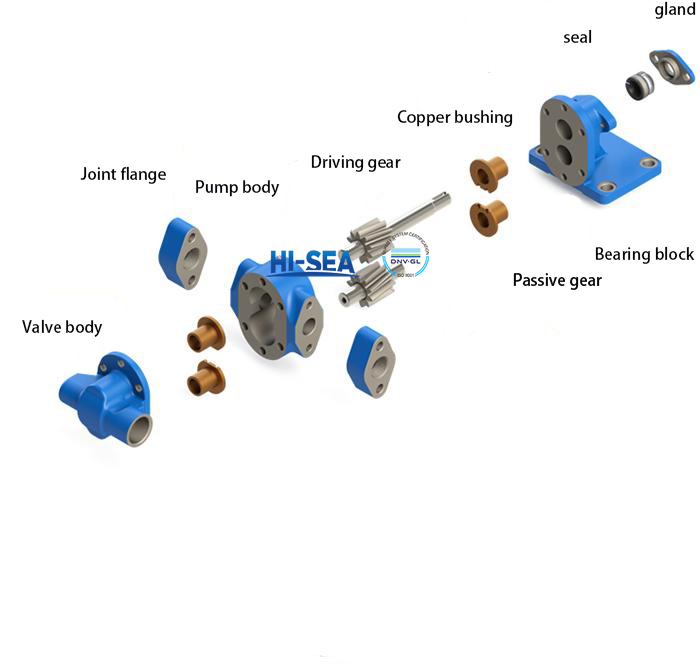

structure

Gear pump is composed of gear, pump body, front and rear cover, safety valve, bearing and sealing device

classification

Generally according to the gear meshing form are divided into external gear pump and internal gear pump

external gear pump: this is the most common gear pump, composed of external gear, simple structure, widely used;

internal meshing gear pump: the inner gear is a hollow upright shaft, and the outer gear is provided with two fixed feet, through which the feet mesh with the inner gear to transport liquid, often used for high-viscosity liquid transport.

Application

The marine gear pump is suitable for conveying non-corrosive lubricating oil or similar liquids without solid particles and fibers, with a temperature below 300℃ and a viscosity ranging from 5×10-6 to 1.5×10-3m2/s (5-1500CST). By reducing the speed, the pump can handle liquids with viscosities of up to 5×104cSt. It can be utilized as a fuel pump, lubricating oil pump, and in other applications.

Lubricating oil pump, fuel pump, etc

material

1.Cast iron: Cast iron is an economic and practical material, often used in the production of high pressure, large flow, low viscosity liquid gear pump. Its advantages are low price, stable performance, corrosion resistance, etc., but low hardness, easy to wear and deformation.

2. Bronze: Bronze is a kind of material commonly used in the manufacture of gear pumps, which has good mechanical properties and corrosion resistance, and can meet some occasions with higher performance requirements for gear pumps. However, the cost is relatively high.

3.Stainless steel: stainless steel can resist the erosion of many chemical media, with high hardness and strength, suitable for the manufacture of gear pumps with high corrosion resistance, but its cost is also relatively high.

4.Aluminum alloy: Aluminum alloy light volume, high strength, low cost, in the production of small, light, high speed, low pressure gear pump is widely used. However, the corrosion resistance of aluminum alloy is relatively poor.

Picture: