What Is A Ejector Pump?

Marine ejector pump is the use of high-speed water flow impact force to push the liquid or push the ship's power components, when the water enters the pump through the injection port, the force of the cyclone inside the pump body, so that the water forms high-speed swirl, the pressure in the pump body is reduced, so that the external liquid is pumped into the pump body through the inlet pipe. As the liquid is pumped into the pump body, the flow accelerates rapidly and is sprayed out through the nozzle.

Overview

Working principle

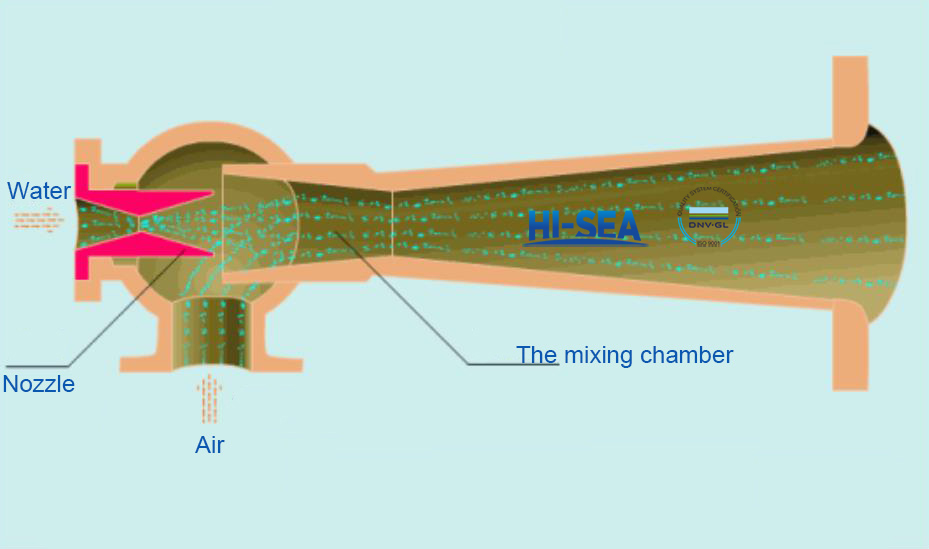

The basic working principle of jet pump:"spray, suction, mixed, expansion":

1.Spray:The injection pump is the use of high-voltage workflow body through the nozzle to produce 25 ~50m/s high-speed jet;

2.Suction:formed in the suction chamber pressure, ejection of transported liquid;

3.Mixed:working fluid wrapped with the ejected fluid into the mixing chamber for mixing together with the energy exchange;

4.Expanded:again diffuser chamber by converting kinetic energy into pressure energy discharge.

Structure

Injection pump consists of a water injection port, an inlet pipe, a pump body, a nozzle and a spray chamber.

Application

The Series of various types of jet pump for ship drainage system or drainage equipment, can also be used for conveying liquid, gas mixture, the mixture of gas and liquid, powder, more suitable for vacuum diversion, vacuum evaporation, vacuum filtration, vacuum drying, deodorizing.

1.Maintaining Ballast Water

During navigation, a ship needs to maintain good stability and equilibrium to keep the waterline at an appropriate position. For this purpose, ballast water needs to be pumped into or pumped out of the ship's ballast water tank. A jet pump can be used when the ballast water tank needs to be filled with water by driving a water pump to suck seawater into the injection pipe and maintaining a good ballast water level.

2. Firefighting System

Ejector pumps are also commonly used in ship firefighting systems because they can provide high-pressure water flow without the need for electricity or fuel and are a reliable firefighting device. In the event of a fire, the jet pump can draw seawater or freshwater into the firefighting pipe to form a high-pressure water stream to extinguish the fire.

3. Wastewater Treatment System

A ship's wastewater treatment system needs to use a pump to discharge the wastewater generated on the ship into the sea. A jet pump can easily draw the wastewater into the digester or filter on the wastewater treatment system and then discharge it out of the ship through the pipe.

Material

1. Polyethylene: Polyethylene is a non-toxic, odorless, white to cream-colored thermoplastic resin with good mechanical strength, corrosion resistance, and wear resistance, as well as good insulation properties and low water absorption. It is often used as the lining material for ship's jet pumps.

2. Polypropylene: Polypropylene is a common plastic material with excellent corrosion resistance and wear resistance, as well as good mechanical strength, low water absorption, and good processing properties and low-temperature performance. It is often used as the base material for ship's jet pumps.

3. Cast iron: Cast iron is an alloy material containing a large amount of carbon, silicon, manganese, etc., with high hardness and wear resistance. It is often used to manufacture the base and impeller of ship's jet pumps, which can ensure its service life and performance.

4. Rubber: Rubber materials have good elasticity, wear resistance, and crack resistance. They are often used to manufacture the lining of ship's jet pumps, which can reduce the friction between the impeller and the lining and protect the impeller from damage.

Picture: