What are the connection methods for marine spiral ducts?

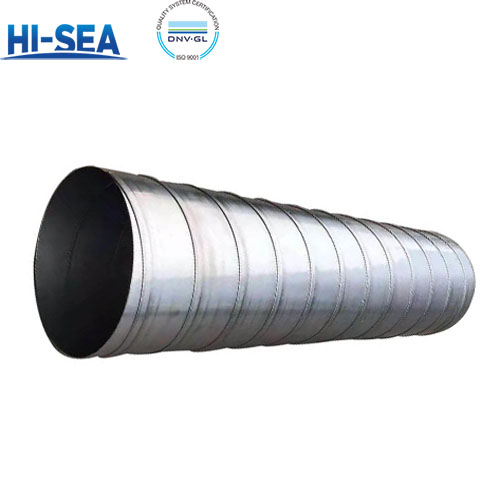

Spiral duct is a common air transportation equipment, it has the advantages of low cost, easy installation, and is widely used in the field of air conditioning and ventilation. In the application process of spiral duct, the connection method is particularly important. Different connection methods will have different effects on the performance, service life and safety of the duct.

Overview

Direct fit connection:

By directly butting the two ends of the spiral air duct, the use of special sealing materials will be tightly connected to the way. This connection has a fast connection speed, simple structure and other characteristics, so it is more commonly used in air duct connection.

Corner joint connection:

The corner joint is fixed on the spiral duct at both ends, and the angle iron is spliced through the bolts, thus connecting different duct segments. This type of connection is suitable for connecting longer ducts, and can improve the stability of the connection.

Flange connection:

A connection method in which both ends of the spiral duct are processed into flanges, holes are made in the flanges, and then bolted together. This type of connection is suitable for connecting larger air ducts, and has the advantages of high strength and good sealing.

Quick-fit interface connection:

The connection port is designed into a special shape of the spiral duct, through the two ends of the duct connection port to fit each other, and then use fast support or fastening and other fast connection devices to fix it together. This type of connection is suitable for frequent disassembly occasions, with the advantages of fast connection speed, easy disassembly and high reuse rate.