Welding Type Zinc Anode for Ship Hull

Common Size(mm):

Length*Width*Thickness

800*140*40/50/60

400/600*120*50

250/300/400/500*100*40

350*150*40/50(two flat iron)

Can be Customized

Overview

Steps of Installation

Preparation: Clean the anode and welding surface to ensure no oil and oxide layer.

Positioning: According to the design drawings, place the zinc anode in the designated location of the hull, usually in the area susceptible to corrosion.

Welding: Attach the zinc anode to the hull using appropriate welding techniques such as arc or gas welding. When welding, make sure that the weld seam is uniform, without inclusions and cracks, so as to ensure the solid connection of the anode.

Inspection: After the welding is completed, check the quality of the weld to ensure that the anode and the hull are well connected.

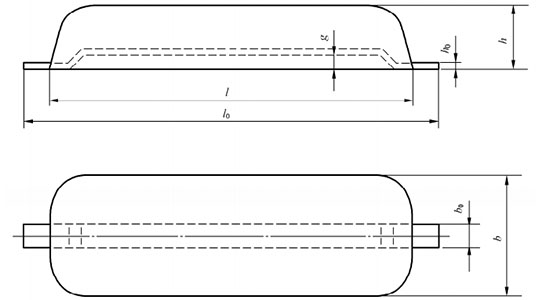

Drawing of Welding Type Zinc Anode with Single Flat Iron for Ship Hull

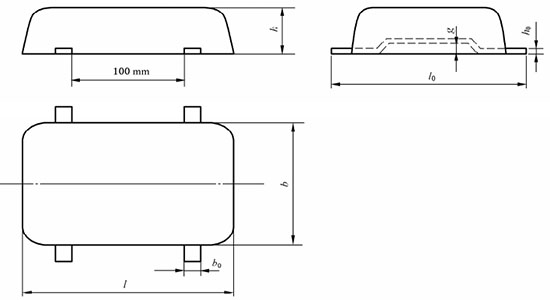

Welding Type Zinc Anode with Two Flat Iron for Ship Hull

Weled Zinc Anodes are Installed on the Ship Hull