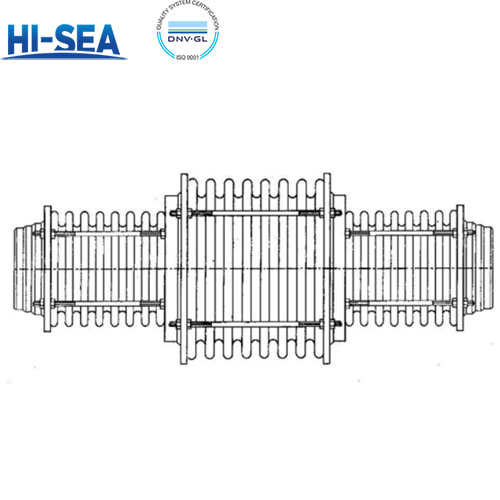

Waist Drum-type Straight Pipe Pressure Balanced Expansion Joint

The waist drum type straight pipe pressure balanced expansion joint is a special corrugated expansion joint, which is mainly used to compensate for the thermal expansion and installation errors in the piping system, to reduce the force on the equipment and to improve the force condition of the equipment.

Overview

Advantages

(1) Compensate for pipeline thermal expansion: the waist drum type straight pipe pressure balanced expansion joint can compensate for the thermal expansion of the pipeline between the equipment and the equipment, reduce the force generated by the installation error on the equipment, so as to facilitate the installation.

(2) Reduce the blind force: the use of bent pipe force balanced corrugated expansion joints can make the equipment is not subject to the role of the blind force generated by the internal pressure, improve the stress condition of the equipment, the equipment is easy to fix.

(3) Simplify the design of fixed bracket: Pressure-balanced expansion joints fundamentally solve the problem of blind force on the thrust of the fixed bracket, simplify the design and construction of the fixed bracket, applicable to the position of the pipeline should not be set up fixed bracket of the high object.

(4) Wide application: it is suitable for high object position upright pipeline or large diameter pipeline where it is not suitable to set up large thrust fixed bracket.

(5) Negative pressure resistance: Straight pipe pressure balancing corrugated expansion joints are negative pressure resistant, effectively offsetting the negative pressure of the pipeline, suitable for absorbing axial displacement within the permissible displacement range and bear the axial pressure thrust of the pipeline loose connection.

(6) Convenient installation and maintenance: installed in the pipeline can be connected to the valve, both to compensate for the expansion and contraction of the pipeline and the valve maintenance provides a convenient.

Nominal Diameter DN mm | Bellows | Axial compensation amount X0 mm | Axial stiffness KX0 N/mm | Radial shape Maximum size B mm | Product Length L mm | Product Type | ||

Total wavenumber n | n1—the bassoon wave number | Connection form | ||||||

Take over J | Flange F | |||||||

Design pressurePD=0.6MPa(6kgf/cm2) Fatigue life [N]=1000 Design temperature t=20℃ | ||||||||

600 | 12 | 4/8 | 53 | 4410 | 1220 | 2250 | 2274 | ZPSK |

18 | 6/12 | 80 | 2940 | 2600 | 2624 | |||

24 | 8/16 | 106 | 2200 | 2950 | 2974 | |||

700 | 12 | 4/8 | 54 | 4945 | 1365 | 2250 | 2274 | |

18 | 6/12 | 80 | 3297 | 2600 | 2624 | |||

24 | 8/16 | 108 | 2473 | 2950 | 2974 | |||

800 | 12 | 4/8 | 45 | 7228 | 1520 | 2250 | 2274 | |

18 | 6/12 | 68 | 4819 | 2600 | 2624 | |||

24 | 8/16 | 90 | 3614 | 2950 | 2974 | |||

900 | 12 | 4/8 | 55 | 4628 | 1670 | 2250 | 2274 | |

18 | 6/12 | 83 | 3085 | 2600 | 2624 | |||

24 | 8/16 | 110 | 2314 | 2950 | 2974 | |||

1000 | 12 | 4/8 | 54 | 5042 | 1840 | 2250 | 2274 | |

18 | 6/12 | 82 | 3362 | 2600 | 2624 | |||

24 | 8/16 | 108 | 2521 | 2950 | 2974 | |||

1100 | 12 | 4/8 | 67 | 3880 | 1986 | 2440 | 2464 | |

18 | 6/12 | 100 | 2990 | 2750 | 2774 | |||

24 | 8/16 | 124 | 1940 | 3110 | 3134 | |||

1200 | 12 | 4/8 | 60 | 5062 | 2130 | 2440 | 2464 | |

18 | 6/12 | 89 | 3375 | 2750 | 2774 | |||

24 | 8/16 | 120 | 2531 | 3110 | 3134 | |||

1300 | 12 | 4/8 | 68 | 5475 | 2266 | 2450 | 2472 | |

18 | 6/12 | 102 | 3650 | 2840 | 2864 | |||

24 | 8/16 | 136 | 2738 | 3230 | 3254 | |||

1400 | 12 | 4/8 | 68 | 5722 | 2380 | 2460 | 2484 | |

18 | 6/12 | 102 | 3815 | 2850 | 2874 | |||

24 | 8/16 | 136 | 2861 | 3240 | 3264 | |||

1500 | 12 | 4/8 | 46 | 8595 | 2530 | 2460 | 2484 | |

18 | 6/12 | 69 | 5730 | 2850 | 2874 | |||

24 | 8/16 | 92 | 4298 | 3240 | 3264 | |||

1600 | 12 | 4/8 | 72 | 4878 | 2688 | 2660 | 2684 | |

18 | 6/12 | 108 | 3252 | 3060 | 3084 | |||

24 | 8/16 | 144 | 2439 | 3450 | 3474 | |||

1700 | 12 | 4/8 | 71 | 6363 | 2868 | 2660 | 2684 | |

18 | 6/12 | 106 | 4242 | 3060 | 3084 | |||

24 | 8/16 | 142 | 3181 | 3450 | 3474 | |||

1800 | 12 | 4/8 | 70 | 6150 | 2968 | 2660 | 2684 | |

18 | 6/12 | 105 | 4100 | 3060 | 3084 | |||

24 | 8/16 | 140 | 3075 | 3450 | 3474 | |||

1900 | 12 | 4/8 | 90 | 4605 | 3128 | 2660 | 2684 | |

18 | 6/12 | 135 | 3070 | 3060 | 3084 | |||

24 | 8/16 | 180 | 2302 | 3450 | 3474 | |||

2000 | 12 | 4/8 | 79 | 7088 | 3288 | 2660 | 2684 | |

18 | 6/12 | 119 | 4725 | 3060 | 3084 | |||

24 | 8/16 | 158 | 3544 | 3450 | 3474 | |||