UV Ballast Water Management System

The UV ballast water management system adopts the technical route of physical filtration + ultraviolet inactivation. Compared with the products of electrolysis and other technical routes, our equipment is simple and reliable in composition, and can be operated with one click to minimize the labor intensity of crew members to the greatest extent.

The core components of the system, such as ultraviolet tubes, ballasts, electronic components, etc., all use imported components from abroad to ensure the stability and reliability of the system, adapt to the special environmental requirements of ships, reduce the consumption of spare parts and accessories, and save costs.

The UV ballast water management system is suitable for various ship types and has been widely installed on various ship types such as bulk carriers, container ships, oil tankers, chemical tankers, asphalt tankers, general cargo ships, salvage ships, semi-submersible ships, heavy lift ships, special transport ships, ro-ro ships, etc.

The R & D, manufacturing, sales and service of green, safe, efficient and energy-saving marine environmental protection products is our purpose. If you have related projects, please contact us.

Overview

Introduction to the Advantages of Core Components

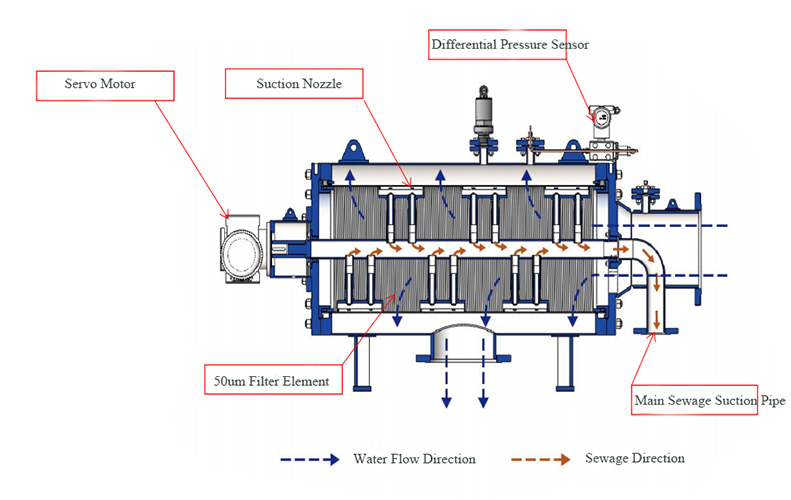

Filter Unit: Negative pressure filter, filtering larger microorganisms and impurities.

Characteristics of negative pressure filter:

▶Low loss of filtration flow, stable water flow.

▶Simple mechanical structure, stable and reliable equipment operation, automatic compensating suction nozzle.

▶Can be installed vertically or horizontally, with flexible layout.

▶Components of internationally renowned brands, long service life, stable and reliable performance.

▶Cleaning control: time control, pressure difference control and manual control.

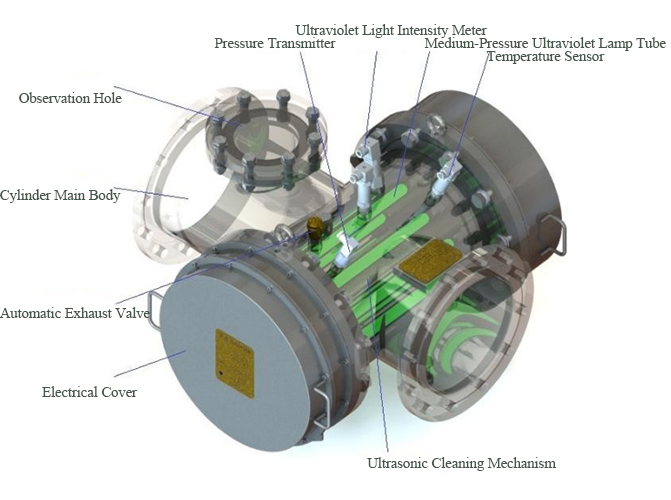

Processing Unit: Medium-pressure ultraviolet inactivation technology, effectively inactivating microorganisms such as algae and bacteria.

Technical characteristics of ultraviolet unit:

▶Unique flexible connection technology, reducing the damage to the lamp tube caused by ship vibration and stress concentration.

▶Wide application range, suitable for various water quality conditions.

▶Adopting the coupling technology of light field and flow field, with good killing effect.

▶Green and environmentally friendly, without any chemical additives.

▶Safe and reliable, without any secondary products.

▶Internationally renowned brand medium-pressure lamp tubes, with an efficient service life of up to 5,000 working hours and low cost of use and maintenance.

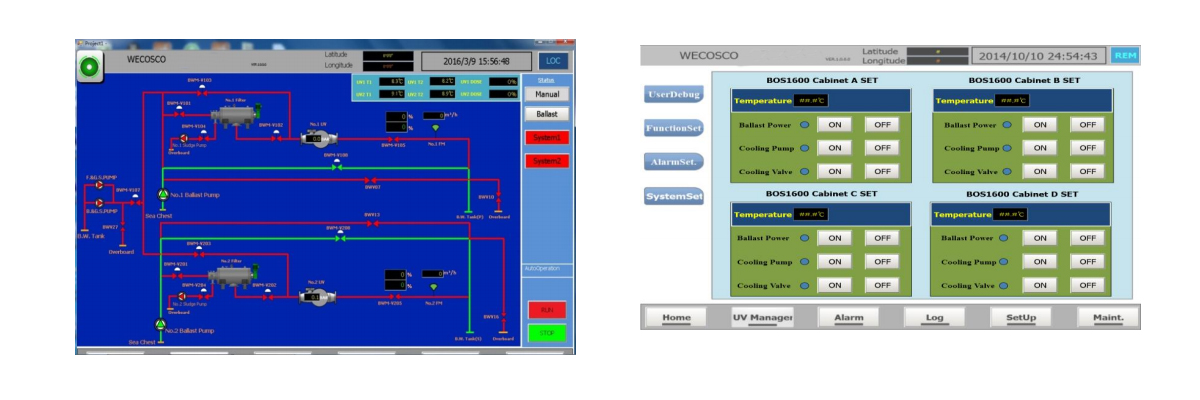

Control Unit: One-click operation, fully automatic control, monitoring system operation.

Characteristics of the control unit:

▶Adopting the internationally advanced PLC automatic control system, one-click operation.

▶B&R/ BEIJER / ESA screen, full touch control.

▶High-quality components, stable and reliable system control, meeting the requirements of the special environment of ships.

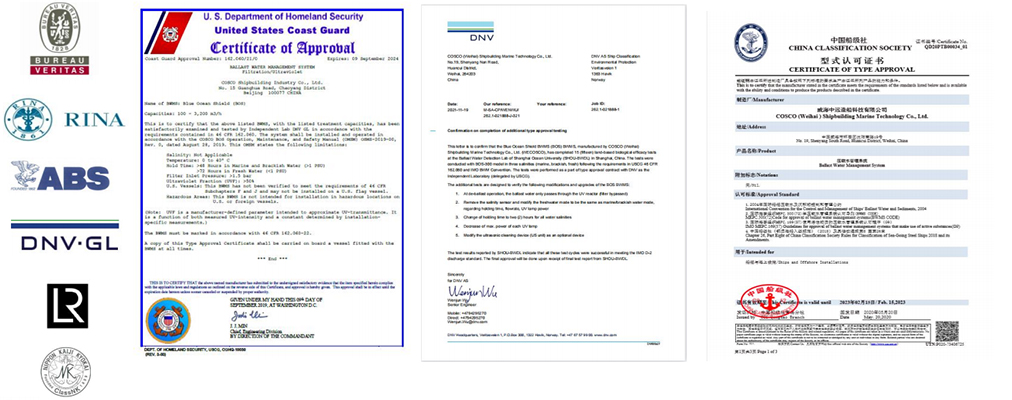

Perfect Product Certification

We are a manufacturer of ultraviolet technology that has obtained USCG TA, and have passed the USCG secondary optimization experiment. Being able to pass all the tests of USCG proves that the equipment has reliable performance. Passing the USCG optimization experiment proves that the adaptability of the equipment on ships is more perfect.

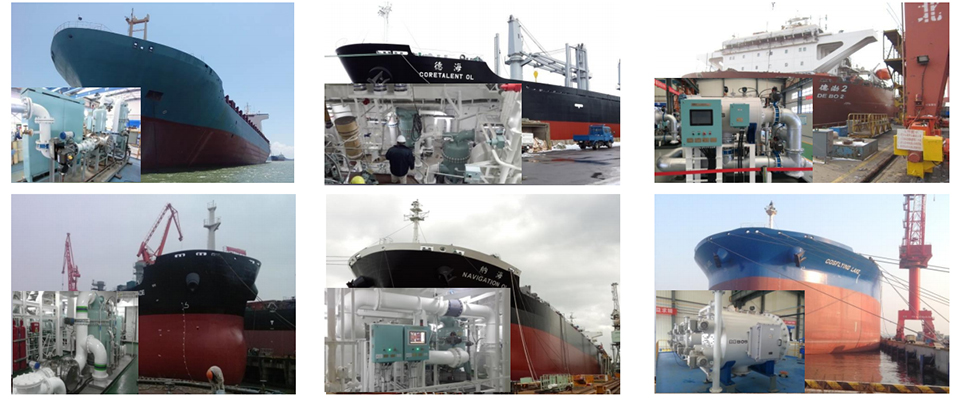

Project Cases

The Haidun Ballast Water Management System is suitable for various ship types and has been successfully installed on various ship types such as bulk carriers, container ships, oil tankers, chemical tankers, asphalt tankers, general cargo ships, salvage ships, semi-submersible ships, heavy lift ships, livestock carriers, and ro-ro ships.

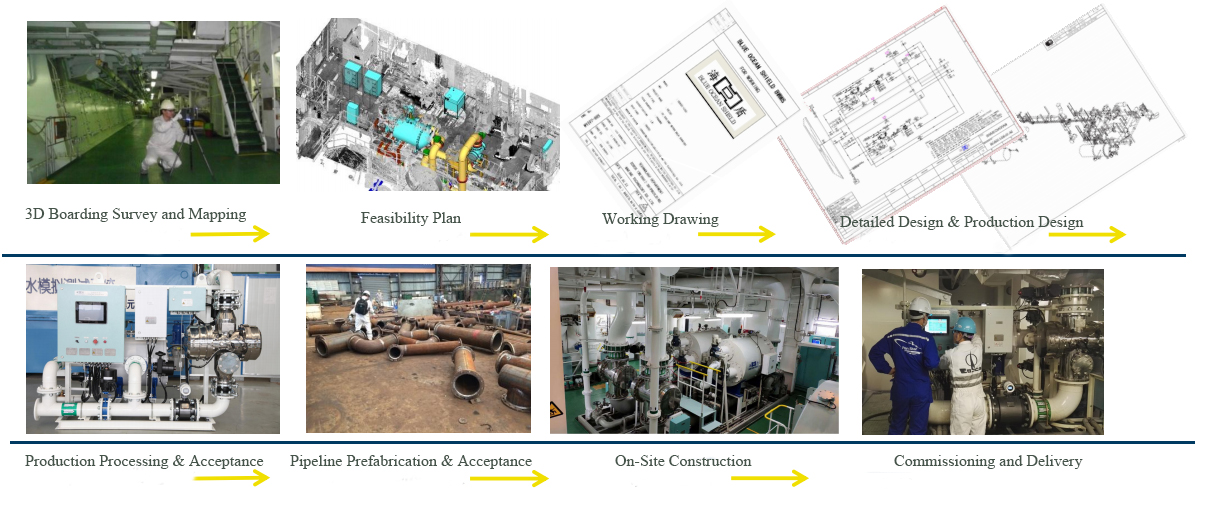

Brief Introduction to the Process of Installing BWMS on Operating Ships

Professional Service Star Team

The existing members of the after-sales service team of the company can independently carry out commissioning, crew training, fault diagnosis and maintenance repair. The after-sales service center coordinates the after-sales service work of all ships, handles the problems reflected by the ships as soon as possible, and provides timely and professional services for shipowners, shipyards and ships.

Establish a one-ship-one-file system. For new ships, starting from the signing of the technical agreement, and for operating ships, starting from the surveying and mapping, throughout all links of design, commissioning, inspection application and after-sales, make sure that there are records to be checked.