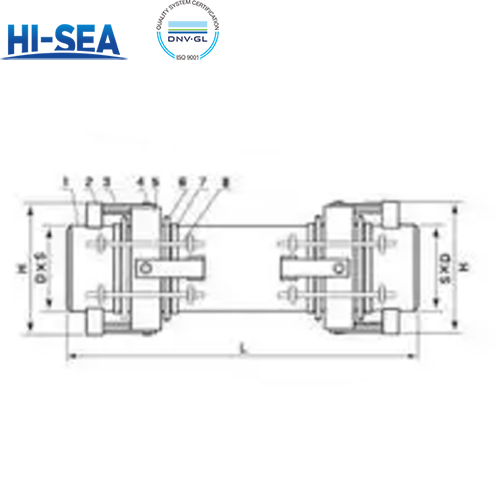

Universal hinged the Lateral Expansion Joint

Universal hinged transverse type expansion joints have two universal expansion joints and intermediate receiver combination, which can absorb transverse deflection displacement in any direction. With high flexibility and adaptability, it can cope with complex pipeline layout and displacement requirements.

Overview

Application Fields:

Iron and steel industry: capable of absorbing lateral deflection displacement and pressure thrust, suitable for a variety of complex piping systems.

Petrochemical industry: able to cope with complex industrial environments, absorbing various displacements and pressures in piping systems.

Power industry: widely used in the piping system of power industry.

The main advantages of universal hinge transverse type expansion joints include:

Advantages

Absorb multi-directional displacement

Compact structure, easy to install

High temperature and corrosion resistant

Wide range of applications

Nominal Path DN mm | Wave Number n | Y0-Horizontal compensation(mm) | L1-Two sections of corrugated pipe center diatance | Angular Rigidity Kθ N.M/( o) | Radial direction Shape Maximum Size B mm | ||||||||||||

Total length L mm | |||||||||||||||||

1500 | 2000 | 2500 | 3000 | 3500 | 4000 | 4500 | |||||||||||

Y0 | L1 | Y0 | L1 | Y0 | L1 | Y0 | L1 | Y0 | L1 | Y0 | L1 | Y0 | L1 | ||||

Design pressurePD=0.25MPa (2.5kgf/cm2) Fatigue life [N]=1000 Design temperature t=20℃ | |||||||||||||||||

100 | 8 | ±128 | 900 | ±199 | 1400 | +270 | 1900 | ±341 | 2400 | 9 | 400 | ||||||

125 | ±107 | ±167 | ± 226 | ±286 | 15 | 44 | |||||||||||

150 | ±91 | ±142 | ±193 | ±244 | 23 | 460 | |||||||||||

200 | ±126 | ±197 | ±267 | ± 337 | 32 | 550 | |||||||||||

250 | ±104 | ±162 | ±220 | ± 277 | 56 | 600 | |||||||||||

300 | ±104 | 850 | ±166 | 1350 | ± 227 | ±288 | 68 | 670 | |||||||||

350 | ±92 | ± 147 | ± 200 | ± 255 | 98 | 720 | |||||||||||

400 | ±80 | ±127 | ±175 | ± 222 | 136 | 770 | |||||||||||

450 | ±105 | 1250 | ± 147 | 1750 | ±189 | 2250 | ± 231 | 2750 | 184 | 82 | |||||||

500 | ± 94 | ± 131 | ±169 | ± 207 | 242 | 940 | |||||||||||

600 | ±119 | 1150 | ±170 | 1650 | ± 222 | 2150 | ±274 | 2650 | 284 | 1050 | |||||||

700 | ± 109 | ±156 | ± 203 | ±250 | 382 | 1110 | |||||||||||

800 | ± 92 | 1100 | ± 134 | 1600 | ±176 | 2100 | ± 218 | 2600 | 522 | 1290 | |||||||

900 | ± 85 | ±123 | ± 161 | ± 200 | 692 | 1390 | |||||||||||

1000 | ±110 | 1500 | ± 147 | 2000 | ± 184 | 2500 | ± 220 | 3000 | ±257 | 3500 | 945 | 1520 | |||||

Design pressurePD=0.6MPa (6kgf/cm2) Fatigue life [N]=1000 Design temperature t=20℃ | |||||||||||||||||

100 | 8 | ±99 | 900 | ± 155 | 1400 | ± 210 | 1900 | ± 265 | 2400 | 16 | 400 | ||||||

125 | ±82 | ± 127 | ±173 | ±218 | 27 | 440 | |||||||||||

150 | ±68 | ±105 | +143 | ±180 | 43 | 460 | |||||||||||

200 | ±82 | +127 | ± 173 | ±180 | 100 | 550 | |||||||||||

250 | ±65 | ±100 | ±136 | ± 172 | 177 | 660 | |||||||||||

300 | ±67 | 850 | ±106 | 1350 | +150 | ± 189 | 208 | 700 | |||||||||

350 | ± 56 | ±90 | +123 | 1850 | ±197 | 2350 | 309 | 750 | |||||||||

400 | ±50 | +80 | ±110 | ± 197 | 432 | 820 | |||||||||||

450 | ±66 | 1250 | ± 92 | 1750 | ±118 | 2250 | ± 144 | 2750 | 593 | 870 | |||||||

500 | ± 57 | ± 79 | ± 102 | ± 125 | 784 | 950 | |||||||||||

600 | ±80 | 1150 | ±115 | 1650 | ±150 | 2150 | ±185 | 2650 | 978 | 1070 | |||||||

700 | ± 72 | ±104 | ± 135 | + 167 | 1077 | 1190 | |||||||||||

800 | ± 58 | 1100 | ± 84 | -1600 | ± 110 | 2100 | ±136 | 2600 | 1510 | 1290 | |||||||

900 | ± 50 | ± 73 | ±95 | ±118 | 2054 | 1450 | |||||||||||

1000 | 1500 | ±84 | 2000 | ±105 | 2500 | ±126 | 3000 | ± 147 | 3500 | 4040 | 1680 | ||||||