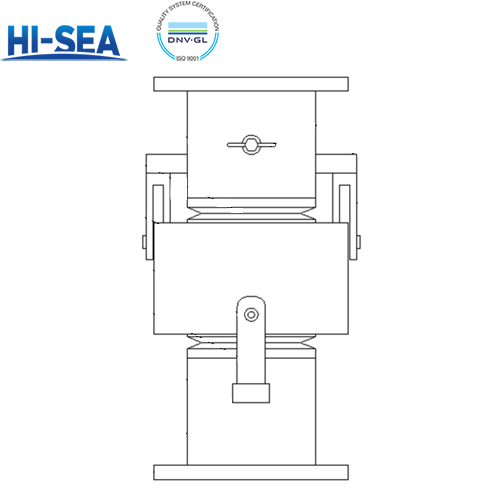

Universal Angle Expansion Joint

Universal angle expansion joints have a universal ring, circumferential two pairs of mutually perpendicular hinge structure, can be more than one direction of displacement and deformation, and can withstand a certain amount of internal pressure thrust, suitable for complex pipe system and need to change the direction of the part of the frequent.

Overview

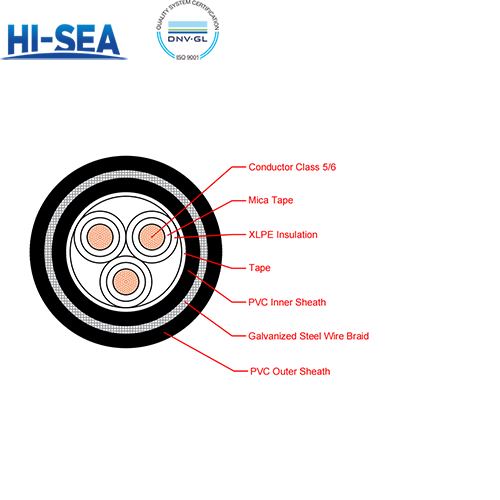

Components:

Bellows: responsible for deformation to absorb displacement. Usually made of stainless steel 304, 316L, 321 and other materials.

Universal ring: capable of absorbing angular displacement in any plane.

Hinge plate: helps to absorb angular displacement.

Flanges and receivers: usually made of carbon steel, stainless steel 304, 316L, 321 and other materials.

Tie rod bolts and nuts: usually made of carbon steel.

Features:

Small volume and light weight: universal angular expansion joints are compact in design and light in weight, easy to install and maintain.

Large compensation capacity: through the combination of two or three pieces, it can compensate for large angular displacement.

Wide range of working conditions: applicable to different working pressures, temperatures and media conditions, such as 0.25MPa to 2.5MPa working pressure, -50℃ to 420℃ working temperature, applicable to liquids, gases and other media.

Nominal Path DN mm | Wave Number n | Angular | Unit pressure Friction torque | Radial shape Maximum Size B mm | Products Factory L mm | Product Type | ||

Compensation amount θ ±(o) | Stiffness Kθo N/mm(o) | The joint pattern | ||||||

Take over J | Flange F | |||||||

Design pressure Pd=1.0MPa (100kgf/cm2) Fatigue life [N]=1000 Design temperature t=20℃ | ||||||||

100 | 4 | 5.0 | 27 | 32.9 | 400 | 600 | 616 | AWJ |

125 | 4.1 | 46 | 46 | 440 | ||||

150 | 3.4 | 74 | 62.1 | 460 | ||||

200 | 3.0 | 225 | 164.2 | 560 | 650 | 670 | ||

250 | 3.0 | 400 | 297.8 | 650 | 674 | |||

300 | 3.2 | 478 | 497 | 700 | ||||

350 | 2.8 | 714 | 859.2 | 760 | 700 | 774 | ||

400 | 2.4 | 1003 | 1072.2 | 870 | ||||

450 | 2.2 | 1378 | 1318.7 | 970 | 900 | 924 | ||

500 | 2.0 | 1827 | 1981.6 | 1000 | 950 | 974 | ||

600 | 3.0 | 2986 | 2812.6 | 1100 | 1000 | 1024 | ||

700 | 3.0 | 1928 | 4272 | 1230 | AWJK | |||

800 | 2.6 | 2661 | 6348.6 | 1360 | ||||

900 | 2.2 | 3560 | 7878.2 | 1600 | ||||

1000 | 1.8 | 10463 | 11177.1 | 1750 | 1100 | 1124 | ||

Design pressure Pd=1.6MPa (16kgf/cm2) Fatigue life [N]=1000 Design temperature t=20℃ | ||||||||

100 | 4 | 3.9 | 52 | 33.2 | 410 | 600 | 616 | AWJ |

125 | 3.2 | 89 | 46.4 | 440 | ||||

150 | 2.6 | 142 | 83.3 | 460 | ||||

200 | 2.5 | 225 | 205.3 | 560 | 650 | 670 | ||

250 | 2.5 | 400 | 357.4 | 710 | 674 | |||

300 | 2.5 | 922 | 666.2 | 810 | 750 | 774 | ||

350 | 2.2 | 1379 | 863.2 | 900 | ||||

400 | 1.9 | 1942 | 1345.9 | 980 | ||||

450 | 1.7 | 2671 | 1654.6 | 1150 | 850 | 874 | ||

500 | 1.6 | 3545 | 2386.1 | 1280 | ||||

600 | 2.2 | 3150 | 3949 | 1350 | 1000 | 1024 | ||

700 | 2.2 | 3507 | 5704.7 | 1400 | 1100 | 1124 | AWJK | |

800 | 1.5 | 4917 | 7282 | 1500 | ||||

900 | 1.8 | 6687 | 10162.3 | 1730 | 1200 | 1224 | ||

1000 | 1.6 | 10618 | 13971.3 | 2000 | ||||

Design pressure Pd=2.5MPa (25kgf/cm2) Fatigue life [N]=1000 Design temperature t=20℃ | ||||||||

100 | 4 | 4.1 | 62 | 43.8 | 430 | 600 | 616 | AWJK |

125 | 3.3 | 105 | 61.4 | 460 | ||||

150 | 2.7 | 167 | 103.4 | 480 | ||||

200 | 2.5 | 476 | 246.3 | 560 | 700 | 720 | ||

250 | 2.5 | 859 | 246.3 | 720 | 724 | |||

300 | 2.6 | 1087 | 476.5 | 820 | 750 | 774 | ||

350 | 2.2 | 1623 | 828.4 | 900 | 800 | 824 | ||

400 | 2.0 | 2282 | 1074 | 1050 | 850 | 874 | ||

450 | 1.7 | 3134 | 1608 | 1160 | 1000 | 1024 | ||

500 | 1.6 | 4155 | 1978 | 1260 | ||||

600 | 1.9 | 5508 | 2774.2 | 1360 | 1100 | 1124 | ||