Triangular Strand Wire Rope

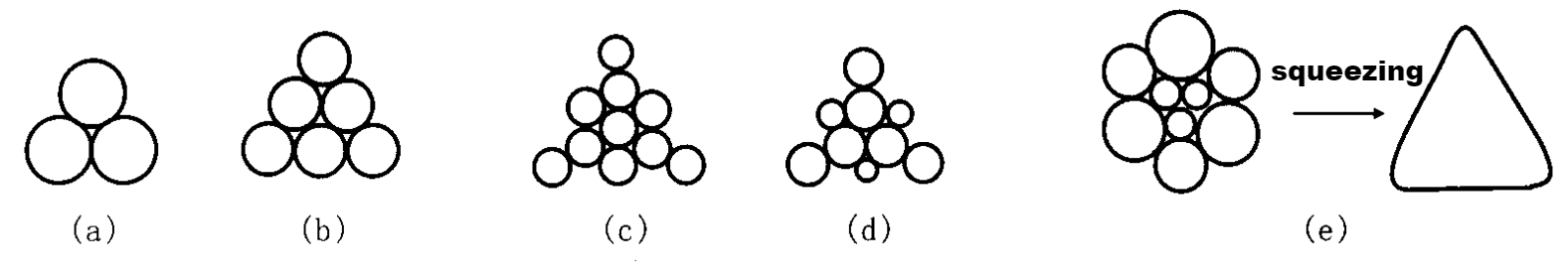

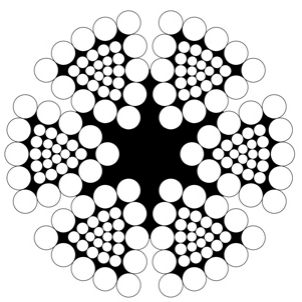

The strand structure of triangular strand wire rope is formed by one or more layers of wires wrapped around a triangular wire or a combination of wires twisted into a triangular core. When compared with round strand wire rope of the same diameter and strength, triangular strand wire rope has a breaking tension that is more than 10% higher, and its abrasion resistance is greatly improved.

Overview

Core types of triangular strand wire rope:

Triangular strand with triangular (V) centre wire:

centre wire.png)

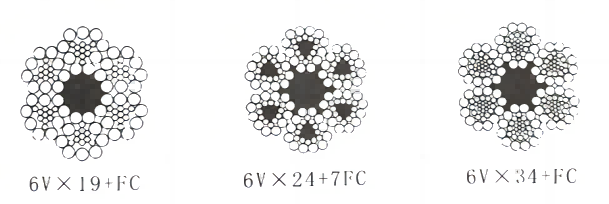

Construction example:

6V×19+FC, 6V×19+IWR, 6V×30+FC, 6V×30+IWR, 6V×34+FC, 6V×34+IWR, 6V×37+FC, 6V×37+IWR, 6V×37S+FC, 6V×37S+IWR

Features:

1. The support area of the steel wire rope is 3 to 4 times larger than that of the round strand steel wire rope, and the contact area with the drum or pulley groove is large. The pressure per unit area during use is significantly reduced, and the wear is reduced and the service life is improved.

2. The triangular strand wire rope has more contact points between strands, so it has good compression resistance and fatigue resistance.

3. The triangular strand steel wire rope has a large density coefficient and a large effective metal cross-sectional area. Compared with the round strand steel wire rope of the same diameter, the total breaking force can be increased by 20~25%.

4. When manufacturing the steel wire rope, a pre-deformation process and a powerful straightening and sizing device are used to effectively eliminate the twisting stress of the steel wire rope.

Cross-sections comparison of round strand wire rope and triangle strand wire rope:

Application:

various equipment for hoisting/derricking/ lifting/drawing, hoisting in vertical shafts, hoisting in inclined shafts(winch), blast furnace hoist, vertical shaft guide and ropeway, winch on slope, excavating machinery etc.