The Production Process of Ratchet Type Load Binder

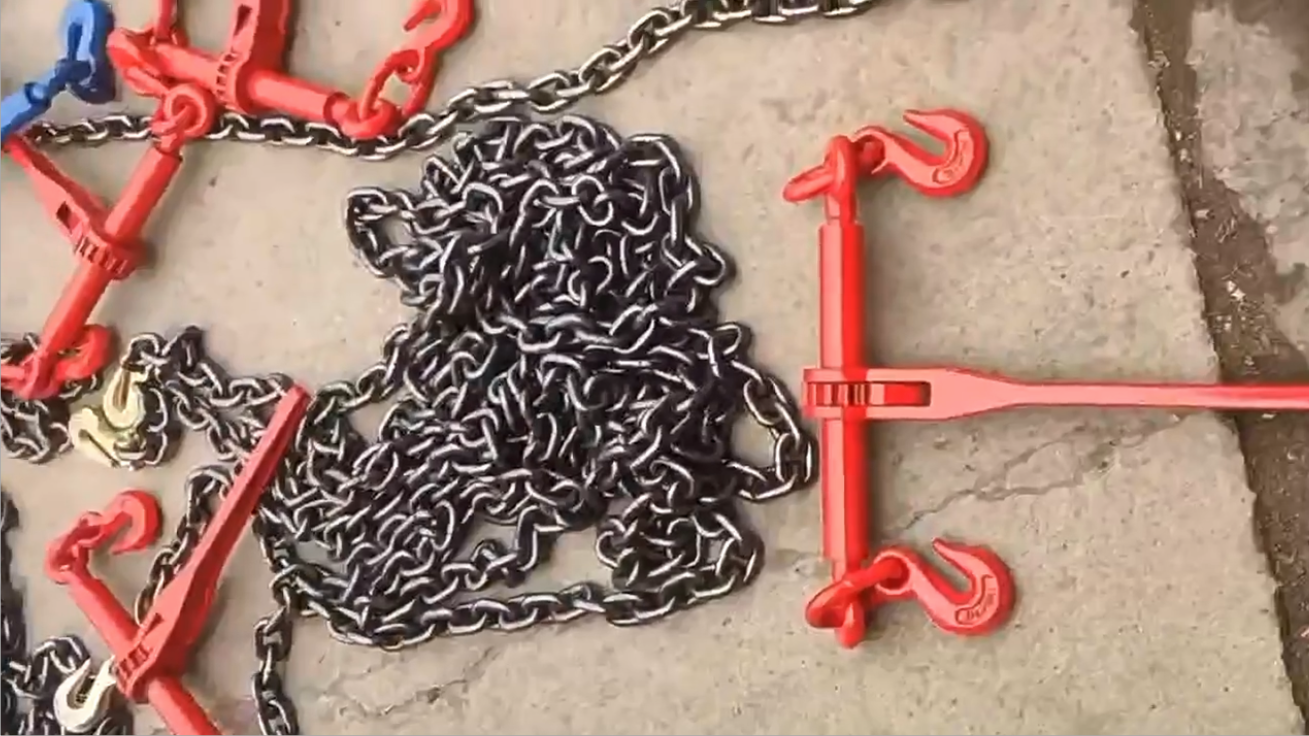

The ratchet type load binder plays a role in securing goods during transportation, movement, loading, or storage. By tightening objects, it prevents them from loosening, ensuring safety and reliability while being lightweight and not damaging the goods. The main production process of ratchet type load binders is die forging. One-piece forging is stronger than casting and easy to install without nuts and other parts.

Overview

The handles of ratchet type load binder can be divided into forged handles and cast handles. Forged handles are mostly made of 45# steel, produced using die forging techniques, while cast handles are made of malleable iron and produced by casting. In addition to the handles, the main components of ratchet type load binders also include a seamless steel pipe, which is generally made of 20# steel.

The threaded rods at both ends of the ratchet type load binder are made by thread rolling and are detachable. The gear part can be produced by die forging or casting. Casting production is more efficient and cost-effective, while the gears produced by die forging may have forging marks, making the rolling process less smooth than cast gears.

Finally, surface treatments for ratchet type load binders can include spray painting, zinc electroplating, or hot-dip galvanizing to improve their corrosion resistance and appearance.