The Main Applications of Rock Wool

Rock wool is based on basalt as an important material, after melting at high temperature, made of artificial inorganic fiber by high-speed centrifugal equipment, at the same time adding special binder and dustproof oil, and then curing by heating, made into various specifications, different requirements of rock wool insulation products. Rock wool, mineral wool can be made into rock wool board, rock cotton, rock wool felt, rock wool blanket (rock wool felt), rock wool pipe and other rock wool products.

Overview

The main application rock wool in the industrial field:

1. Engine Room and Equipment Spacing Fire Protection System

For the high-temperature environment of ship main engines, auxiliary engines, boilers, and hot oil systems, we offer professional solutions:

Recommended Technical Specifications:

Density: 140-160 kg/m³

Thickness: Determined based on thermal calculations, typically 50-100 mm

Thermal Conductivity: ≤0.038 W/(m·K) (at an average temperature of 70°C)

Hydrophobicity: ≥99%

Maximum Operating Temperature: 650°C

Application Advantages:

Reduces engine room noise to within the requirements of IMO MSC.337(91)

Reduces heat loss and improves fuel efficiency by approximately 3-5%

Meets A-60 fire compartmentation requirements, providing 60 minutes of fire protection

2. Class A Fire Separation between Living and Public Areas

To meet SOLAS fire protection requirements for shipboard living and service areas, a complete fire separation solution is provided:

Bustel and Deck Systems:

A-60 Class Separation: 50mm thick rock wool board

B15 Class Separation: Single layer 50mm thick rock wool board

B0 Class Separation: Single layer 25mm thick rock wool board

Material Properties:

Acidity coefficient ≥1.8, ensuring fiber chemical stability

Slag ball content (particle size >0.25mm) ≤7%

Compressive strength (10% deformation) ≥40kPa

Dimensional stability (24h, 650℃) ≤1%

Piping System Insulation

Pipeline System | Recommend Products | Thickness Range | Special Requirement |

Stem Pipeline | Rock wool | 40-80mm | Outer layer of aluminum foil moisture-proof layer |

Fuel Oil Pipeline | Rock wool | 30-50mm | Anti-oil penetration treatment |

Freezing Water Pipe | Rock wool | 25-40mm | Moisture-proof vapor barrier layer |

Air Conditioning Wind Pipe | Rock wool | 20-35mm | High surface flatness |

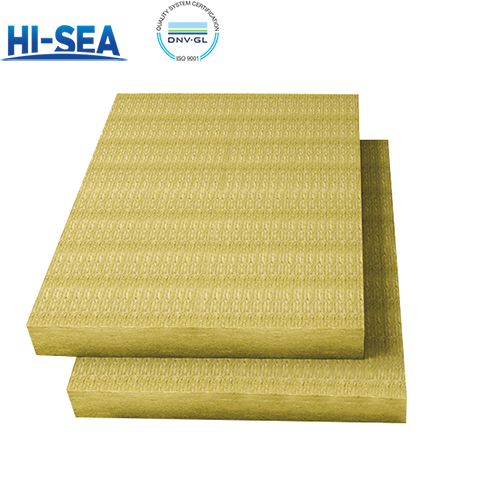

Picture of Rock Wool