The Differences Between Rock Wool and Glass Wool

Rock wool and glass wool are common thermal insulation materials, which are widely used in construction, industry and other fields. Although the two are similar in function, there are significant differences in material source, production process, physical characteristics, application field and cost.

Overview

The difference between rock wool and glass wool is mainly reflected in the following four aspects

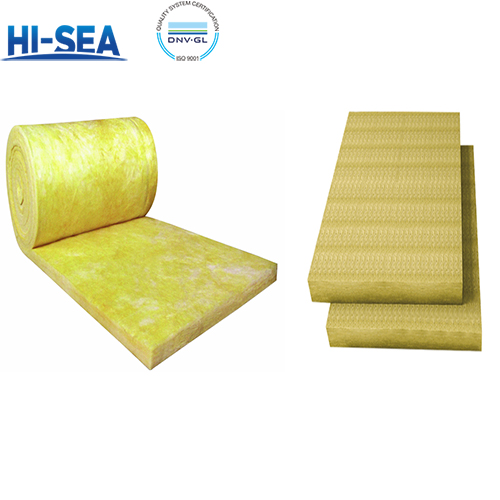

1. Different appearance

Glass wool is bright yellow, while rock wool is gray, and the difference is obvious.

2. Different bulk density

Rock wool of the same volume is much heavier than glass wool, and the compressive strength of rock wool is greater than that of glass wool

3. Different manufacturing materials and processes

Glass wool is a kind of glass fiber. The main material is glass and other ingredients that are melted at high temperature, and then centrifuged into glass fiber. After multiple processes, it is solidified, shaped, and cut into glass wool products. Rock wool products are made of high-quality basalt, dolomite and other main raw materials. After high-temperature melting, they are formed into fibers by centrifugal equipment, and then special adhesives are added to solidify and process into products of various specifications.

4. Different Refractory temperature and applications

The fire-resistant temperature and application scenarios are different. Glass wool is generally used for insulation parts below 260 degrees Celsius, mostly used for insulation of the top floor of general buildings, sound absorption, low-temperature pipe insulation and insulation of refrigerated and insulated warehouses. The maximum use temperature of rock wool can reach 600 degrees Celsius, and it is mostly used for insulation of boilers and various industrial equipment in the petroleum, electric power, metallurgy, textile and chemical industries, as well as insulation and sound absorption of partitions, ceilings and exterior walls in the construction industry.

Main Comparison

Comparison | Glass Wool | Rock Wool |

core raw materials | Recycled glass and quartz sand | Natural basalt and dolomite (higher melting point, more stable) |

Fiber properties | The fibers are relatively long and elastic, but also quite brittle. | The fibers are shorter but stronger and have higher mechanical strength. |

Operating temperature | Typically ≤ 260°C | Long-term temperature resistance ≥ 600°C, with excellent stability at high temperatures. |

Fire resistance | Generally, it is a Class B flame-retardant material. | Natural A-grade non-combustible material is a recognized fire barrier. |

Density and strength | It has a lower density and relatively weaker compressive and tensile strength. | Higher density, significantly better compressive and tensile strength, suitable for load-bearing structures |

hygroscopic | The performance is relatively low, but it deteriorates significantly after getting damp. | It has a high water repellency rate, dries easily after being exposed to moisture, and its performance is well restored. |

Core application scenarios | Low-temperature pipeline insulation | Fire protection for ship bulkheads/decks (A60/A30), high-temperature industrial equipment, and buildings with high fire protection requirements. |