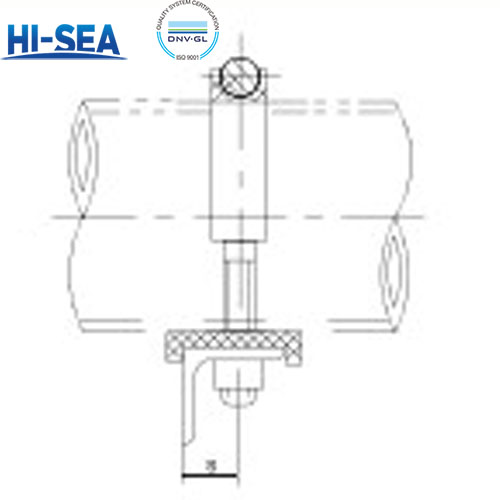

Ta Type U Pipe Hanger

Ta type U pipe hanger is a device used for pipe support and fixing, mainly used in hydraulic, pneumatic system and other aspects of various pipe fixing, applicable to oil, water, gas as the medium of the pipeline.

Overview

It consists of U-shaped studs and pads, connected by bolts, and the materials used are high-quality carbon steel, 304, 316 stainless steel.

Advantages

Long-distance pipe fixing: particularly suitable for long-distance pipes to prevent them from sagging or deforming due to weight and running pressure.

Highly adjustable: thanks to the bolt connection, the degree of fastening can be adjusted as needed, making it suitable for pipes of different diameters and different application scenarios.

Corrosion resistance: good corrosion resistance, especially suitable for piping systems in wet environments or exposed to chemicals.

Maintenance and Care Recommendations

In order to ensure the long-term stable use of the pipe hangers, regular inspection and maintenance is recommended:

Regular inspection of fasteners: no loosening of the fasteners of the studs and pads to ensure the stability of the hanger.

Cleaning and Maintenance: Clean the hanger and its accessories regularly to prevent accumulation of dust and impurities affecting its performance.

Anti-corrosion treatment: Appropriate anti-corrosion treatment is applied to the exposed parts to prolong the service life.

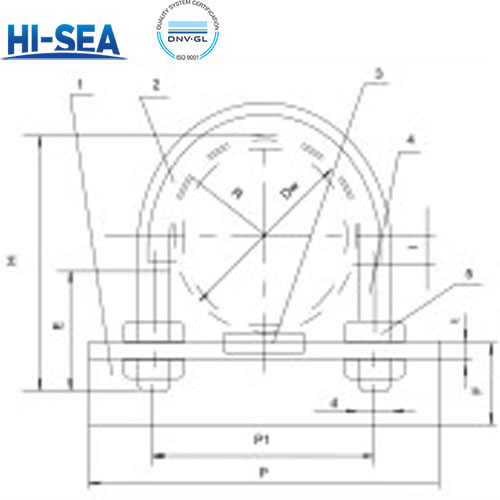

U-Stud | Pipe O.D.Dw | Basic Size of Ta pipe Hanger | Weight kg | ||||||||

R | d | H | E | P | t | P1 | F | t | s | ||

15 | M8 | 22 | 45 | 80 | 5 | 38 | 40 | 5 | 22 | 0.09 | |

18 | 27 | 50 | 30 | 88 | 44 | 0.13 | |||||

21 | 34 | 55 | 96 | 50 | 0.15 | ||||||

25 | M10 | 42 | 65 | 104 | 60 | 0.21 | |||||

28 | 48 | 70 | 34 | 110 | 66 | 0.29 | |||||

34 | 60 | 85 | 120 | 78 | 0.35 | ||||||

42 | M12 | 76 | 105 | 45 | 154 | 6 | 96 | 50 | 6 | 30 | 0.39 |

49 | 89 | 115 | 167 | 110 | 0.58 | ||||||

61 | M16 | 114 | 145 | 55 | 204 | 7 | 138 | 63 | 8 | 35 | 0.93 |

74 | 140 | 175 | 230 | 164 | 1.37 | ||||||

88 | M20 | 168 | 205 | 258 | 8 | 196 | 1.86 | ||||

101 | 194 | 230 | 60 | 300 | 222 | 80 | 40 | 2.37 | |||

114 | 219 | 255 | 324 | 248 | 2.63 | ||||||

127 | 245 | 285 | 348 | 874 | 2.95 | ||||||

141 | 273 | 310 | 378 | 302 | 3.3 | ||||||

167 | M24 | 325 | 370 | 74 | 454 | 358 | 90 | 10 | 50 | 5.59 | |

182 | 355 | 400 | 484 | 10 | 388 | 6.85 | |||||

193 | 377 | 420 | 504 | 410 | 8.63 | ||||||

207 | 406.4 | 450 | 534 | 438 | 100 | 9.73 | |||||

217 | 426 | 470 | 554 | 458 | 10.55 | ||||||

233 | M30 | 457 | 505 | 80 | 592 | 12 | 496 | 10.97 | |||

244 | 480 | 530 | 570 | 518 | 11.63 | ||||||

258 | 508 | 560 | 85 | 642 | 546 | 125 | 12 | 11.98 | |||

269 | 530 | 580 | 650 | 568 | 12.19 | ||||||

284 | 558.8 | 610 | 700 | 598 | 13.22 | ||||||

560 | 13.7 | ||||||||||

309 | 610 | 660 | 744 | 648 | 14.5 | ||||||

319 | 630 | 880 | 770 | 668 | 14.97 | ||||||