T6 Serial Dredging Cutter Teeth

Dredging cutter teeth are essential components of dredging equipment used to cut and remove sediment, rocks, and debris from bodies of water. These teeth are typically made of high-quality steel or carbide material to ensure durability and longevity in harsh dredging conditions.

The design of serial dredging cutter teeth is crucial for efficient dredging operations. These teeth are usually shaped with sharp edges and cutting surfaces to effectively break up and remove material from the seabed or riverbed. The teeth are attached to the cutter head of the dredging equipment and rotate to cut through the sediment.

Dredging cutter teeth come in various sizes and shapes to accommodate different types of dredging projects. They can be designed with different cutting angles and configurations to optimize performance and productivity. Some teeth may also have wear-resistant coatings or hardfacing to extend their service life and reduce maintenance costs.

Overview

Dredging cutter teeth play a critical role in the dredging process by enabling efficient material removal and ensuring the smooth operation of dredging equipment. Proper maintenance and replacement of these teeth are essential to maximize the performance and longevity of the dredging equipment.

Features

1. Flared chisels are used for peat, sand and soft clay

2. Narrow chisels are applied in packed sand and firm clay

3. Self sharpening of the tooth, better ground penetration, increased production.

4. Teeth with pick points are used for rock.

5. Increased lifetime, decreased frequency and duration of maintenance.Advance investment casting technology for producing with low cost.

6. Increased lifetime, decreased frequency and duration of maintenance.

7. Can be customized according to your requirements or can provide OEM service.

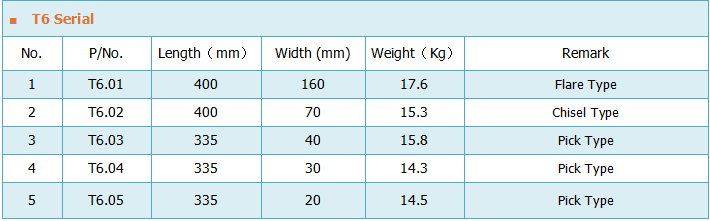

Technical parameters of T6 Serial Dredging Cutter Teeth