Structure and type of sliding watertight rudder bearer

Sliding watertight rudder bearing is a key component used in ships, mainly for supporting and sealing rudder shafts in underwater environments. Its main functions include:

Provide support: Slide the watertight rudder bearing to support the rudder shaft, ensuring smooth operation in underwater environments, reducing friction and wear.

Maintain watertightness: The rudder bearing needs to have good sealing performance to prevent water from entering the steering gear compartment or cabin, ensuring the watertightness of the ship.

Shock absorption: The sliding watertight lower rudder bearing can also absorb and alleviate the vibration and impact of the rudder shaft during operation, protecting the rudder shaft and related mechanical components.

Overview

The lower rudder bearing refers to the rudder bearing that is generally only capable of withstanding radial forces and is installed at the point where the rudder stock penetrates the outer plate of the ship. This type of rudder bearing is usually made of corrosion-resistant materials, such as bronze, stainless steel, or high-strength synthetic materials, to adapt to the corrosion of seawater environments. In the specific design and manufacturing process, it is also necessary to consider the size, purpose, and special requirements of the ship's navigation environment.

For more marine rudder system components, kindly please click here.

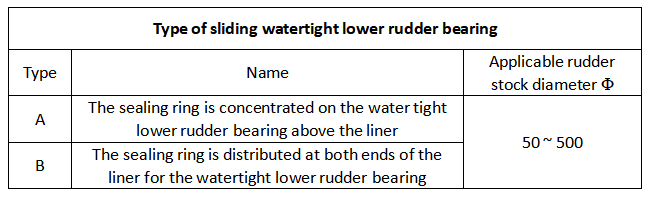

Type of sliding watertight lower rudder bearing:

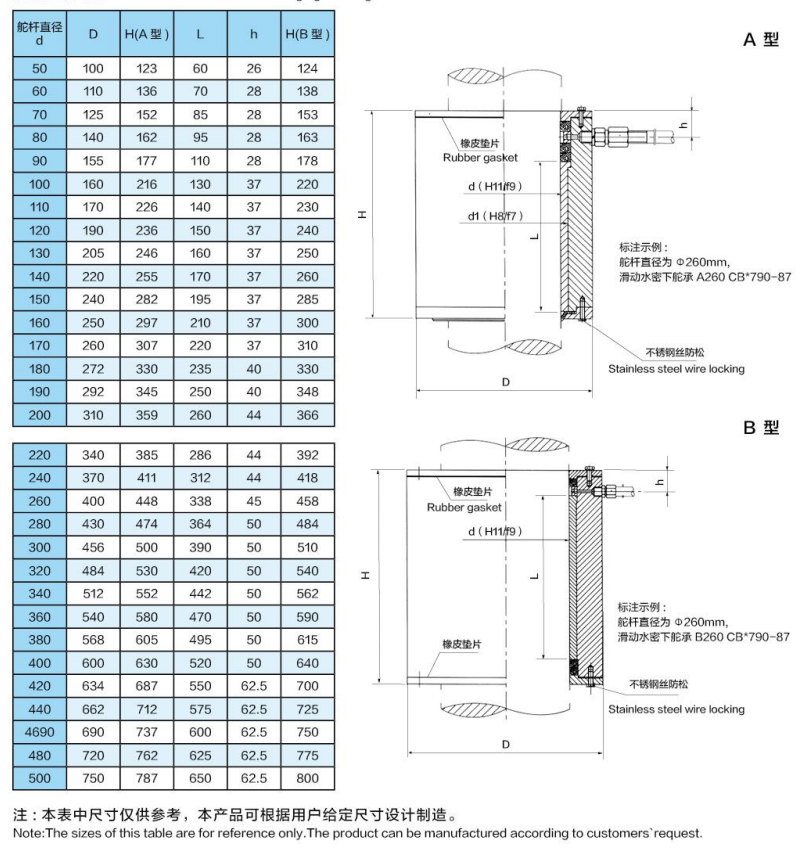

The structure and main parameters of sliding watertight lower rudder bearings:

Performance or requirements for sliding watertight lower rudder bearings:

1. The surface of the body should be smooth and free from cracks, sand holes, and other defects that affect strength.

2. The load-bearing body should be welded to the bottom of the ship. Elbow plates should be added during installation to enhance stability and stiffness.

3. Fasteners should be galvanized.

4. The rudder bearing should be inspected and accepted by the technical inspection department of the manufacturing plant, and a certificate of conformity should be issued.